|

|

|

Steam Valve Problems

|

Unless

like me you own one of the first three Stafford's built by Station Road

Steam you will not encounter the problems described below because all

subsequent engines have been fitted with an improved valve

incorporating a PTFE valve seat. |

|||||

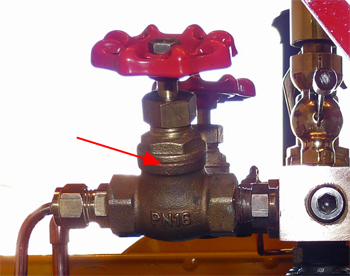

One

of the steam control valves (actually the steam blower valve) is shown

in the photo with an arrow pointing to the gasket that seals the joint

between the valve body and the spindle section. At various

times

in the early days of operating the Stafford the spindle sections of

several valves became loose and steam leaked from this joint.

It's an easy job to get the spanner out and tighten the

spindle

section back into the body, BUT you must open the valve a couple of

turns first. If you don't, and the valve is left in the

closed

position, as you tighten the spindle section you will force the valve

very firmly into its seat and probably end up with a score mark on the

valve. Scoring will prevent it from seating properly with the

result that it will constantly leak steam to whatever it feeds. One

of the steam control valves (actually the steam blower valve) is shown

in the photo with an arrow pointing to the gasket that seals the joint

between the valve body and the spindle section. At various

times

in the early days of operating the Stafford the spindle sections of

several valves became loose and steam leaked from this joint.

It's an easy job to get the spanner out and tighten the

spindle

section back into the body, BUT you must open the valve a couple of

turns first. If you don't, and the valve is left in the

closed

position, as you tighten the spindle section you will force the valve

very firmly into its seat and probably end up with a score mark on the

valve. Scoring will prevent it from seating properly with the

result that it will constantly leak steam to whatever it feeds.This leads directly to how we damaged one of the injector steam control valves; when a rather heavy handed driver that I allowed to drive over tightened the injector steam valve a few times. As mentioned on several other pages of this website the steam control valves only need to be closed gently, not wrenched tightly shut. As a result of the over tightening the valve would no longer completely stop the flow of steam to the right hand injector so it was replaced to stop the injector becoming over heated by a constant steam flow without any feed water. Unfortunately the same valve suffered the problem again in late 2011, so the Stafford has now had two new valves as a result of them being over tightened. These problems aren't a fault of Station Road Steam or the Stafford they are solely down to the operator, so if you own one of the first three engines produced take care and close the valves gently. Another problem became apparent during 2012 when the loco had covered about 200 miles. On this occasion steam started leaking in a very fine (almost invisible but still scalding) jet from an injector steam valve. This was traced to the valve gasket which had hardened and then cracked. A check then revealed that all three of the other valves had gasket washers in a similar state. A phone call to Station Road Steam showed that it would be difficult to buy replacement valves of this type because they only stock the current type of valve. Since they are superior I decided to change all four valves for the current design, although Station Road Steam informed me that I would have to "tweak" the pipes a little as the new valves are wider than the originals. You can read about what happened next on the Functional Modifications pages. |

||||||