|

|

|

Teething Troubles

| The problems on this page are what I would call the teething troubles, and the only really nasty one was a seized slide bar which a design change for batch two onwards has fully overcome. So if you purchase a Stafford just keep an eye out for anything working loose as the loco "runs in" and you shouldn't have anything to worry about. | ||||||

|

1) Mechanical

Lubricator and its Check Valve. I

found the first of the teething problems by chance before I took the

Stafford to the track. When I first received the locomotive

the

mechanical lubricator had a lid held in place with four Allen screws

and a small filler cap on it so you could fill it with steam oil.

As the

whole lubricator was mounted close underneath the saddle tank pouring

in thick oil from any form of container was obviously going to be very

difficult and you could never see how much oil the tank contained.

So I phoned Station Road Steam and asked them how they did

it.

The answer was that they only left one screw in place so that

the

lid could be rotated to open up the lubricator tank for filling and

visual inspection of the oil level. I didn't like that idea,

so I

made a new lid that simply clipped in place. Job done !

The next problem was spotted a couple of days before I was due to make my first run with the Stafford when I saw that there was no longer any oil in the lubricator tank. As it obviously hadn't run out anywhere it had to have gone into the steam feed pipe but I knew that the check valve between the lubricator and the pipe should have stopped that happening. The ability of the oil to "escape" had been a fluke as I had just happened to leave the lubricators ram in the fully back position (which left the ram intake port open) when I had previously manually operated the lubricator. The cause of the problem was also found to be a fluke. During the Stafford's build the check valve spring had not been inserted into the check valve. A quick phone call to Station Road Steam had a spring arrive by post the next morning ready for the first run. |

|||||

2) Slide Bars. 2) Slide Bars.My

Stafford was one of the three built in the first production run, but I

was probably the last to run the loco as I had spent a couple of months

after it had been delivered building the driving trolley and waiting

for a members running day (the 1st Sunday of a month) at my club track.

Then with just a couple of days until my scheduled first run

I

received an e-mail from Station Road Steam informing me that one of the

other locos in that group of three had suffered a seized crosshead, and

that as result the design of the slide bars had been changed.

The

new bars had slots milled into them to retain the lubrication oil and

holes drilled through them to transfer the oil to the bottom face.

They were also nitrided, which would give a hard

surface to

prevent the galling that had led to the seizure and also have

the

effect of reducing friction. The plan was for a pair of bars

to

be posted to me which I would then fit in place of the possibly suspect

items. The problem was that these new slide bars wouldn't

arrive

in time for the next club member's day.

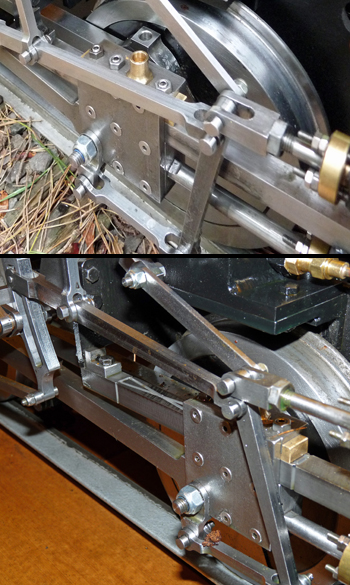

After talking it over with Station Road Steam we decided to run anyway on the basis that the prototype Stafford had run many hundreds of miles without a problem, and that only one of the three production locos had seized. Needless to say that my Stafford only managed two laps of the Pinewood track before suddenly coming to a dead stop half way round the third lap. While the adults stood about and tried to decide how we could manually lift the Stafford onto a flatbed wagon to recover it one of the junior members pointed out that all we needed to do was slide the loco back a few feet onto the sector plate of the adjacent carriage shed, and then by slackening the pivot bolt the sector plate could be used as a ramp to slide the Stafford onto the wagon. Definitely a good reason to have junior club members around ! The Stafford was duly recovered, and less than 48 hours later it was collected by Station Road Steam. Then on the next club members day they brought it back, complete with new slide bars, and spent the morning with the Pinewood members as just about everyone there including all the junior members had a go at driving it. Of course every Stafford now has the new slide bars fitted, and the photo here shows the original (photographed when seized) and the revised slide bar design. The lower photo clearly shows the milled oil ways. If you look at the lower photo you may also notice that some of the bright steel work seems to be rusty. This had me rushing to the garage as I had only just finished cleaning the loco and didn't remember seeing any rust. Thankfully it turned out to be a trick of the light, with a combination of the cameras flash and the oiled surfaces reflecting the saddle tank colour. |

||||||

| 3)

Piston Rod. The

third teething problem was heard just a few laps into the Stafford's

first day of work hauling passenger trains at Pinewood. The

train

had just reached cruising speed after leaving the station when I first

heard a slight knocking noise, but it disappeared when we started to

climb the hill and then came back once over the crest.

The passengers were dropped at the station and the

Stafford

was taken out

of service and into the yard. After a lot of head scratching by

various people

the loco, still in steam, was raised on wooden blocks and the noise was traced to the

right hand cylinder.

Soon afterwards the problem was traced to the piston rod

which had started to unscrew itself from the crosshead.

A quick turn of the spanner soon resolved the problem for the day; and

once home both piston rods were unscrewed, degreased, and fitted back

with a bit of Loctite Screwlock to ensure that they wouldn't come loose

again.

|

||||||

| 4)

Other loose parts. During

the first year of operation a few other sundry parts have worked loose,

but in part that was my fault for not checking them during routine

maintenance and cleaning. The most notable and important was

probably when I found a bolt on the floor of my van when I got home

from the track. Eventually I traced it to the front nearside

axle

block retaining strap that was just about hanging on by the very end of

the only remaining bolt. As these bolts are right underneath

the

loco they are not easy to see or access, but all of them were

subsequently removed, degreased, and replaced with the addition of some

Loctite Screwlock.

|

||||||