|

|

|

Storage and Transport

The

Stafford Class saddle tank weighs about 230 Kilos (the best part of a

quarter of a ton) when ready to run so if you intend to store it at

home and transport it to a track you will need to consider how you will

be handling the loco. It is possible to get a Stafford into

the

back on many estate cars, mine was actually delivered (with the funnel

removed) in

a VW Passat estate, and it will easily fit into most "people carriers"

(MPV's) but I wouldn't recommend just leaving it loose in the back of

the vehicle. The consequences of a 1/4 ton loco being hurled

into

the back of your seat in even a mild accident just don't bear thinking

about. Carrying the loco in a trailer is safer for the

occupants

of the car, but from past experience with my traction engines I found

that most small trailers give a very rough ride for the engines.

So regardless as to whether you use a trailer or a car you

will

really need to secure the loco to stop it moving about. The

Stafford Class saddle tank weighs about 230 Kilos (the best part of a

quarter of a ton) when ready to run so if you intend to store it at

home and transport it to a track you will need to consider how you will

be handling the loco. It is possible to get a Stafford into

the

back on many estate cars, mine was actually delivered (with the funnel

removed) in

a VW Passat estate, and it will easily fit into most "people carriers"

(MPV's) but I wouldn't recommend just leaving it loose in the back of

the vehicle. The consequences of a 1/4 ton loco being hurled

into

the back of your seat in even a mild accident just don't bear thinking

about. Carrying the loco in a trailer is safer for the

occupants

of the car, but from past experience with my traction engines I found

that most small trailers give a very rough ride for the engines.

So regardless as to whether you use a trailer or a car you

will

really need to secure the loco to stop it moving about. I also found another unexpected problem when I tried to carry my Stafford in an MPV. The vehicle had a solid sill just inside the tailgate, so I built two lengths of track from aluminium angle and mounted them on a wooden framework that rested on the tailgate sill and a solid looking floor section between the 2nd and 3rd rows of seats. Once the loco was loaded onto the track I left it for 30 minutes and was horrified to see that the loco, track and supports were all slowly tipping over. The problem was that the floor between the seats was high density structural form, not metal. So I rebuilt the supports to have a very large base covering most of the "real" floor of the MPV behind the front seats, but the same problem occurred because that floor was also foam. Similar materials are also present in the load areas of many modern estate cars, so it looks as if current vehicles are not capable of securely carrying heavy model steam locos. You could try covering the entire load area of the vehicle with a thick sheet of plywood to distribute the load; but depending on the ratio of the area of the foam to the unsupported areas to fit around things like folding seats, spare wheels, or storage boxes you may still have a problem to stop the foam being crushed. Also, if you want to transport both the loco and a driving trolley it is likely that the loco will not be central in the vehicle's load area and this uneven loading will probably result in the loco tipping over again. Thankfully when I found these problems I hadn't managed to sell the van I had previously used to transport my Tasker traction engine, so that ended up as the Stafford's transporter. With the recent demise of the van the MPV has been replaced with a crew cab van that has a nice solid steel load floor (at the expense of comfort for the family !). |

||

With

the transport sorted out I set about building a storage trolley for the

locomotive using 40x40x3mm mild steel angle to carry a pair of rails

made from 30x60x5mm unequal mild steel angle. The structure

was

simply MIG welded together and mounted on a set of heavy duty

industrial castors so that it could be pushed around the garage and

aligned with the van for loading. The photo shows the

finished trolley, with points to note being the slotted brackets for

the loading bridge to rest in and the "set back" of the bridge brackets

in relation to the trolley front wheels. This "set back"

ensures

that the weight of the loco on the 1.5 metre long loading bridge

remains inside the

trolley wheelbase so that it does not tip up as the loco crosses the

"bridge". Obviously the track height above the floor should

be

the same as that in your transport vehicle so that you don't have to

push or pull the Stafford up and down hills as you load (although as

you may observe in the photo you can still have a problem if your

driveway slopes). Believe me; dragging the Stafford up that

slope

at the end of a day is hard work. To ensure that the storage

trolley and loading bridge stay connected to the van while loading /

unloading I fitted a 8mm diameter steel pin to the front of the bridge

that locates in a hole between the rails fitted to the van. With

the transport sorted out I set about building a storage trolley for the

locomotive using 40x40x3mm mild steel angle to carry a pair of rails

made from 30x60x5mm unequal mild steel angle. The structure

was

simply MIG welded together and mounted on a set of heavy duty

industrial castors so that it could be pushed around the garage and

aligned with the van for loading. The photo shows the

finished trolley, with points to note being the slotted brackets for

the loading bridge to rest in and the "set back" of the bridge brackets

in relation to the trolley front wheels. This "set back"

ensures

that the weight of the loco on the 1.5 metre long loading bridge

remains inside the

trolley wheelbase so that it does not tip up as the loco crosses the

"bridge". Obviously the track height above the floor should

be

the same as that in your transport vehicle so that you don't have to

push or pull the Stafford up and down hills as you load (although as

you may observe in the photo you can still have a problem if your

driveway slopes). Believe me; dragging the Stafford up that

slope

at the end of a day is hard work. To ensure that the storage

trolley and loading bridge stay connected to the van while loading /

unloading I fitted a 8mm diameter steel pin to the front of the bridge

that locates in a hole between the rails fitted to the van.Back with the trolley; the wooden sections to either side and between the track are removable for loco maintenance, although my preferred method (when weather permits) is to support the loading bridge outer end on a wooden trestle so that I can roll the Stafford out of the garage for easier all round access. The second in the trolley in the photo supports the Stafford's driving truck (which is also too heavy to be a comfortable one man lift), while the lower decks of each trolley can be used to store items such as my 5" gauge driving wagon. While stored the loco and wagons are simply covered with cloth dust sheets to keep spiders at bay. Using cloth as opposed to plastic seems to stop the metal sweating as the temperature changes, and thus helps prevent rusting of the unpainted steel parts of the loco. |

||

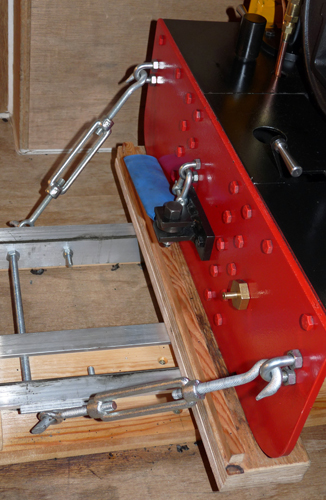

The

final point relating to storage and transport was learnt the hard way. The

final point relating to storage and transport was learnt the hard way.To stop the Stafford moving around during transport I used four 10mm wire rope grips ("U" bolts) with two fitted to each buffer beam as shown in the photo. The saddle section of each grip was not fitted, so it was simply a case of drilling two 8mm diameter holes through the buffer beam to mount each grip and then using M8 steel full nuts to attach the grips. The 8mm turnbuckles could be hooked through each rope grip and over a peg securely attached to the track (which was in turn bolted into the van). I naively assumed that this would keep the Stafford safely in place during transport. For the first two trips to and from the Pinewood Miniature Railway I had no problems, but near the end of the third journey to the track I heard (and felt) a heavy thump as something suddenly moved. It turned out that the Stafford had managed to get loose and was no longer sitting on the track. Somehow I managed to lift it back onto the track by myself and completed the journey, but a quick check showed that the problem had occurred because the Stafford was able to rock around as its suspension flexed when the van bounced over bumps in the road. The solution was simple, and just entails wedging a length of plywood under each buffer beam so that as the turnbuckles are tightened the Stafford's springs are compressed until the loco is rigidly clamped against the blocks. Since then I have never had a problem with transporting the Stafford. Incidentally, the blue "thing" in the photo is a length of plastic sleeving that is slipped over the drawbar to prevent it from damaging the buffer beams paint when the loco is not in use. The photo also shows the 8mm wire rope grip and 5mm shackle that are used to attach a safety chain between the loco and the driving trolley. I personally think that it is highly unlikely that the driving trolley would ever get detached from the loco as it is fixed with an 8mm bolt and nyloc nut at the loco end and an 8mm pin and "R" clip at the trolley end. However it's better safe than sorry, and many other clubs that I visit demand that such a safety chain is fitted. |