|

|

|

Ending the Day

|

Hopefully

you have had a good day running your Stafford and are returning to the

loco yard to finish the day, so if possible you now need to pick a good

parking spot to shut down the loco.

If you have access to a raised steaming bay then head for it, but if

not try to stop over an inspection pit. Wherever you stop,

try to

make sure that the boiler blowdown valve is not over a support or

anything else that may get in the way when you conduct the blowdown.

Once stopped, with the regulator closed, reversing lever centred, and handbrake on, and all the steam control valves closed, the first thing to do is to drop the fire. You could simply undo the two firebox cover plate thumbscrews and remove the entire grate assembly from the boiler but there are a couple of problems with doing so. First, everything is very hot and you will almost certainly be dropping burning coals over the Stafford. Secondly, with the grate assembly missing the residual warmth of the boiler will cause the natural draught of the funnel to pull lots of cold air through the boiler tubes. This isn't very good for them as they may cool faster than the boiler and develop small leaks where they are fitted into the boiler. The better solution is to use your firing shovel to remove the burning coals from the grate and dispose of them in a suitable container. You can also shovel out most of the ash from below the grate at the same time which will make the next task of cleaning the Stafford somewhat less messy. With the fire disposed of use an injector to fill the boiler with water almost to the top of the sight glass. This will both help to cool things down a little and also make sure that the blowdown will have an effect on as much of the boiler as possible. The saddle tank drain cock can then be opened to start draining the water, which can take a surprisingly long time. Now you need to wait for the boiler pressure to drop to about 45 psi, so you have some time to put things away or have a cup of tea. An interesting point to note while you are waiting is that if you try to remove the blowdown valve access plate from the footplate you will probably find that it is very tightly wedged in place. This shows you how much the boiler has expanded while hot. Eventually, when the boiler pressure is down to about 45 psi you can start the blowdown procedure which will hopefully remove some of the calcium etc. that builds up in the boiler. Make sure that the area under the blowdown valve is clear, and then partially open the blowdown valve to let the boiling water blast out. This makes a very effective scalding pressure washer to clean the concrete (or whatever else) is beneath the Stafford, so take care not to get your feet in the way. After quite a while the boiler pressure will start to fall, and when it reaches about 20 psi you can fully open the blowdown valve. Note: If you don't have access to a raised track and the Stafford is standing on the track or over a shallow pit you will need to be even more careful when you open the blowdown valve as the scalding water will hit the ground and spray in all directions. When the blowdown eventually stops and all the water has been blasted out of the boiler leave the blowdown valve open and open all the steam control valves a turn or two to ensure that as the metal cools and contracts the valves don't become stuck solidly against the valve seats. The residual heat of the boiler should now dry out the inside of the boiler ready for storing the loco. |

||

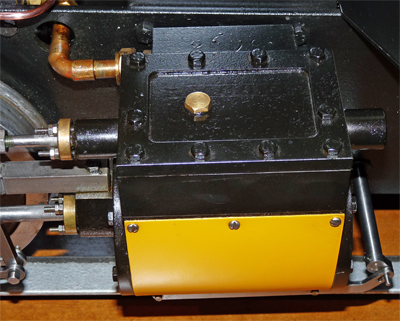

The

next task is to get some oil into the two cylinders so that they don't

rust before you next use the Stafford. The photo shows the

oiling

cap which is fitted to the valve chest cover on top of each cylinder.

As delivered they were painted black, but the spanner soon

started to chip the paint so on Gentoo the paint was removed to make

the two caps look tidier. The

next task is to get some oil into the two cylinders so that they don't

rust before you next use the Stafford. The photo shows the

oiling

cap which is fitted to the valve chest cover on top of each cylinder.

As delivered they were painted black, but the spanner soon

started to chip the paint so on Gentoo the paint was removed to make

the two caps look tidier.The caps are easily removed using a suitable spanner, but take care not to lose or damage the small rubber 'O' ring that seals them. Use an oil can to put some light oil (spare "new" 10/40 car engine oil is about right) into the valve chest through the oil hole, then open the cylinder drain cocks, put the reversing lever fully forward, release the handbrake, and push the Stafford a few feet forward along the track. Add some more oil, pull the reversing lever fully back, and pull the Stafford back again. Repeat this procedure until the oil is spurting out of the drain cocks as you push the Stafford along the track, and then do the same for the other cylinder. After this leave the cylinder drain cocks open (but remember to put something under them in the car or when stored at home to catch the oil that will drip out). Now refit the two oil caps, but don't over tighten them or you will simply squeeze the 'O' ring out from under the cap. Finally, give all the bright steel parts a good spray with WD40 to displace any water and prevent rust from forming. That's the after running work over with, so you can now take the Stafford home and set about cleaning it up. |