|

|

|

Injector and Clack Valve Problems

|

The

injector and clack valves had been giving me problems during the first

two years that I owned my Stafford, with the clack valve often tending

to stick partly open if an

injector failed to start properly when steam was applied. The

original of this page was written at a time when I believed the problem

may have been caused

by "dirt" adhering to the clack valve ball, but as the balls

always remained clean throughout the second year that I owned my

Stafford that line of investigation was obviously incorrect.

However I could still cause an injector clack to stick

partly open by following a simple sequence of events so my

investigations had to continue. As it seems to be relevant my

test method to create the problem is described below. The "End of Day" test. "Fire up" the Stafford and once the steam pressure has been raised to over 110 psi test both injectors to demonstrate that they, and their clack valves, work correctly. The Stafford is then operated for several hours using only one injector. Then with anything over 80 psi on the gauge the other injector is tested again. On my Stafford this guaranteed that the injector would not start and that when the injector steam was shut off the clack valve would stick partly open so that the boiler would start to lose all of its water. On my Stafford this was normally an unrecoverable situation, so the fire had to quickly be dropped to prevent possible boiler damage. Obviously it could be argued that I shouldn't create the problem in the first place, but my concern was that if an injector failed to start during normal operation then the clack problem could occur. This has happened to me on several occasions, especially when novice drivers were at the controls who may not have been very knowledgeable about operating injectors. After several months of operating my Stafford I had developed an operating regime that generally prevented the problems from occurring. This entailed: 1) only using one injector all day 2) using that injector at least every five minutes (even if the loco was parked for a lunch break) 3) keeping the boiler pressure between 80 and 95 psi. Step 3 was possible because (in my experience of operating passenger trains at Pinewood) the Stafford would run out of grip before it ran out of power even at 80 psi. Using the lower boiler pressure also meant that the safety valve would not open. If you have every witnessed a Stafford safety valve opening you will have seen its "violence", which has children running away in fright and everyone in the vicinity complaining about the hot shower. This is best avoided during public running ! However despite operating this regime there were still occasions when, normally due to operator error, an injector did not start and even though only 80 psi was showing on the pressure gauge the clack valve stuck partly open. Several Stafford owners have also contacted me via this website to discuss problems with injectors failing to start, but only one other person has mentioned having a similar clack valve problem. |

|||||

|

Observations and Analysis of the

Problem

Throughout the miserably cold Spring and Summer of 2012 my Stafford was generally only used for passenger services at Pinewood as there was little incentive to run it at any other time, and the operating regime detailed above ensured that I had no problems with the injectors or clack valves. However when the first hot operating day occurred in mid August the "in use" injector failed to start cleanly even though only 80 psi was on the gauge and the clack valve stuck partly open requiring the loco to be taken "out of service". This started me thinking about the problem and what I had learnt during almost two years of operating my Stafford and reading about injectors and clack valves. Thankfully I also had plenty of notes about my locos failures to review. I believe the key points to be: 1) Both injectors always work perfectly at any boiler pressure over 50 psi when the loco is "steamed up" at the start of a day. 2) The injector is more likely to fail to start properly (once the loco has been in steam for more than an hour) if the boiler pressure is over 100 psi. 3) The injector is more likely to fail to start properly, even with boiler pressures as low as 80 psi, when the ambient temperature is high. 4) The clack valve problem only ever occurs when an injector has failed to start properly. I have never seen the clack valve fail if the injector has successfully "pumped" water into the boiler. 5) The injector and clack valve problem is more likely to occur if the saddle tank is less than half full of water. The common denominator here was starting to look like being "temperature". At the start of the day everything is cold, as the day progresses everything starts to get hot, and a full saddle tank is most likely to have been filled with cold water. Remarkably at the exact time that I arrived at this conclusion I was contacted by an American Stafford owner Frank Cook who was also having problems with his injectors failing to operate. After discussing my thoughts about temperature Frank explained that in Kentucky he was operating his Stafford in high ambient temperatures, and he then conducted some tests on his loco to see if temperature did have an effect. His results are shown below.

Not surprisingly Frank's conclusion was that "it appears as if the problem resides with the temperature of the water in the saddle tank". My own comment 5) above also reflects Frank's findings because a full saddle tank of water has most probably been recently filled with cool water while a nearly empty saddle tank will have had time for the remaining water to be heated up by the boiler. While Frank was conducting his experiments I reflected on my experience with the traction engines that I had previously owned. Both traction engines stored their water under the footplate where it would get heated by the boiler heat conducted from the firebox through the engine's side frames that also formed the sides of the water tank. On both traction engines the injector could be difficult (if not impossible) to start when the feed water was hot, and my solution was to use the driving trolley electric water pump to put more cold water from the driving trolley water tank into the footplate tank (if necessary allowing it to overflow) until the water temperature became low enough to allow the injector to start. Applying similar reasoning to my Stafford's problems I concluded that anything I could do to lower the feed water and injector temperatures would probably be a help. |

||||||

| Further Thoughts and Possible

Solutions Injectors for model steam engines are designed to operate between specific minimum and maximum pressures, most commonly I believe about 40 to 100 psi. As explained in the excellent book "Miniature Injectors Inside and Out" by D A G Brown injectors require several internal component dimensions to be adjusted to alter their designed operating pressure range. At the top of this page (Item 3 of my "Operating Regime") I stated that keeping the boiler pressure below 100 psi seemed to help to prevent injector problems, and it is my view (with apologies to Station Road Steam if I am wrong) that the Stafford's injectors are probably operating beyond their intended operating pressure range once over 100 psi. Certainly the injectors supplied on my Stafford look like (and measure up as) "off the shelf" items which most probably were intended for that more normal 40 to 100 psi operating range. All the experience gained seems to show that the injectors will operate at 120 psi when the loco is initially steamed up, but as the temperature rises (either due to "heat soaking" whilst in steam or simply due to hot weather) then the injector is more prone to not operating satisfactorily. One idea that has crossed my mind is to feed an injector directly with water from a tank in the driving trolley. This water would probably (in the UK at least) be cooler than the saddle tank water which is always being warmed by the boiler, feed water temperature being critical as demonstrated by Frank Cook's experiments detailed above on this page. Another solution that has been developed by an Australian Stafford owner Roger Walker is to replace one of the injectors with an electric water pump. Roger uses a 12 volt electric pump normally used for commercial window washers and has mounted the pump and a 12 Volt battery in his driving truck with "quick release" connectors to connect the water feed and return to the Stafford. The electric pump is freely available on EBAY if you search for "Propump diaphragm pump"+"160psi" and currently sells for about £60 in the UK. With a working pressure of 160 psi and a pump rate of 5.5 litres per minute the pump is more than sufficiently rated to meet the requirements of pumping water into the Stafford's boiler. As of mid September 2012 Station Road Steam has been supplying some Stafford owners with injectors configured to work at higher boiler pressures. I attended one owner's test of his replacement injector and it certainly seemed to operate consistently at boiler pressures approaching 120 psi but its lowest operating pressure seemed to be about 70 psi. If this modification becomes standard then the locos will have to have one "high" and one "low" pressure injector fitted to cover the full likely boiler pressure range as not having a way to feed water into the boiler below 70 psi would not be a very good idea. A self imposed lower operating boiler pressure also helps to prevent injector problems, but nothing so far explains why my Stafford's clack valves are prone to sticking partly open when an injector fails to operate satisfactorily. I have noticed that it only seems to happen when the injector fails due to temperature / boiler pressure and not simply when the driver fails to operate the steam valve in a way that correctly starts the injector. This leads me to believe that the clack problem is connected to the injector problem, but at the time of writing this page the physical explanation for this connection still eludes me. However one possible solution to the clack valve sticking partly open may be to alter the physical characteristics of the clack valve and so with the help of another Pinewood member I have designed, built and fitted a pair clack valves that use an O Ring to form the pressure seal as opposed to the ball bearing. |

||||||

| Successful Modifications to my

Stafford's Injector System During the last quarter of 2012 I have incorporated three changes to my Stafford that have made significant improvements to the operation of the injectors and clack valves. The first modification was to replace the "metal seat" steam valves (only ever fitted to the first three Stafford's manufactured as Batch 1) with "PTFE seat" steam valves. This modification stopped steam constantly leaking into the injector, thus lowering its temperature. Prior to the modification small wisps of steam could always be seen escaping from the injectors overflow pipes, but after the valves had been replaced almost nothing could be seen escaping. You can read more about this modification on the Functional Modifications pages of this website. The second modification made was to revise the layout of the plumbing for the injectors so that the pipes and the injectors were relocated to slightly cooler positions. This modification is detailed nearer the bottom of this page. The third modification made was to replace the original ball bearing clack valves with valves using O Rings to create the valve seal. This modification is also detailed at the bottom of this page. With this modification fitted the last traces of steam escaping from the injector overflow pipes have ceased. Each of these modifications was made in sequence and thoroughly tested on the Stafford, especially with the "End of Day" test, to determine what effect the modification had on the Stafford's injector system performance. Now with all of the injector and clack valve modifications fitted both injector systems are operating perfectly at any boiler pressure and the Stafford has become a very different engine to drive. I can't yet claim to have fully resolved the high ambient temperature problem as demonstrated by Frank Cook's test data, but the difference in my Stafford's behaviour is remarkable. For the first time since I purchased the loco over two years ago I now have full confidence in the injectors working at any boiler pressure, and if due to operator error the injector does not start then the clack valve always seats fully to prevent leakage of the boiler water. I have even been able to operate the Stafford with boiler pressures over 110 psi for extended periods without any injector or clack problems occurring, and on the odd occasion when I have failed to start an injector correctly the clack valve has always closed completely. This, for me, is a huge step in the right direction and the "End of Day" test has never been failed since all three modifications have been completed. By mid 2013 the Stafford had covered over 150 miles with the modifications fitted and its performance has been flawless. Even during the so called "Heat Wave" of July 2013 the injectors and clack valves always operated perfectly and at last I have total confidence in my Stafford. |

||||||

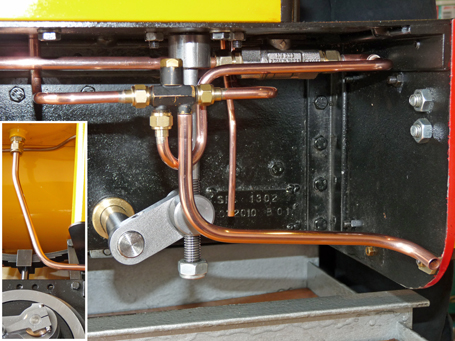

Injector System Plumbing

Modifications The

intention of the modification was to keep the injector and its feed

water as cool as possible and so the injector was relocated to the

outer edge of the footplate and the feed water pipe moved away from its

position alongside the chassis frame. Previously both had

been

neatly fitted very close to the chassis frame alongside the firebox. The

intention of the modification was to keep the injector and its feed

water as cool as possible and so the injector was relocated to the

outer edge of the footplate and the feed water pipe moved away from its

position alongside the chassis frame. Previously both had

been

neatly fitted very close to the chassis frame alongside the firebox.The photo shows the modifications I made with the injector relocated to 20mm below and 20mm in from the outer edge of the footplate. The injector water control valve has also been rotated through 90 degrees to lie "fore & aft" rather than "across" the loco which allows the feed water pipe to be kept away from the chassis frame, and as shown in the inset section of the photo the pipe from the saddle tank is simplified by not using the original set of three 90 degree bends. The steam pipe to the injector and the feed pipe to the clack valve have been replaced with extended versions, and a new pipe only using one 90 degree bend section has been made to connect the water valve to the injector. The photo also shows the extension to the injector overflow that enables the driver to see what is going on (water flowing, nothing visible when the injector is operating correctly, or steam if the injector is not working). The other thin vertical pipe visible in the photo is the boiler gauge glass drain pipe. |

||||||

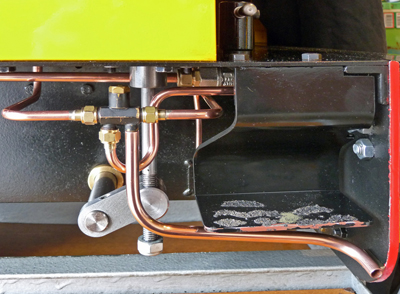

The

photo on the right shows how the footplate step (see the Cosmetic

Modifications section of this website) provides a degree of physical

protection for the modified injector system. The

photo on the right shows how the footplate step (see the Cosmetic

Modifications section of this website) provides a degree of physical

protection for the modified injector system.My Stafford has now covered over 150 miles with this modification in place and the "End of Day" test (see the top of this page) has been conducted on many occasions without the injector failing to start. This seems to have been a step in the right direction and both injectors on my Stafford now have this revised layout. I have also rotated the water control valve knob through 90 degrees so that the On and Off orientations remain as supplied by Station Road Steam to avoid confusing any potential drivers who may be familiar with the normal Stafford controls. |

||||||

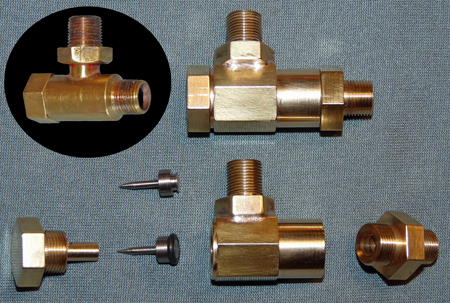

O Ring Clack

Valves In

the conventional ball bearing clack valve as fitted to the Stafford's,

and almost every other model steam engine in use today, the seal is

simply formed by the ball bearing dropping into a round hole in the

valve seat. Normally this works perfectly well, is simple to

make, and is a very long life component capable of operating at any

likely boiler water temperature. However for some reason that

I

can't explain on my Stafford if an injector failed to start as a

result, I believe, of high temperature / boiler pressure as opposed to

simple operator error of the steam control valve then the clack valve

would normally stick partially open. A fellow model engineer

at

Pinewood suggested that I try an O Ring clack valve as they tended to

seal better than ball bearings in the hope that the change may resolve

the problem. An alternative would have been to try a Nitrile

rubber ball bearing in place of the stainless steel ball bearing but

previous experience with trying them on my traction engines had put me

off that idea. I had previously found that the Nitrile ball

could

become stuck in the seating hole which would prevent the injector from

operating, and Nitrile rubber's maximum operating temperature of 120

degrees Centigrade is less than the Stafford's boiler water temperature

of 172 degrees

Centigrade at 120 psi. Small Viton O Rings are quite easily

available and can operate at temperatures up to 200 degrees

Centigrade so they became my preferred option. In

the conventional ball bearing clack valve as fitted to the Stafford's,

and almost every other model steam engine in use today, the seal is

simply formed by the ball bearing dropping into a round hole in the

valve seat. Normally this works perfectly well, is simple to

make, and is a very long life component capable of operating at any

likely boiler water temperature. However for some reason that

I

can't explain on my Stafford if an injector failed to start as a

result, I believe, of high temperature / boiler pressure as opposed to

simple operator error of the steam control valve then the clack valve

would normally stick partially open. A fellow model engineer

at

Pinewood suggested that I try an O Ring clack valve as they tended to

seal better than ball bearings in the hope that the change may resolve

the problem. An alternative would have been to try a Nitrile

rubber ball bearing in place of the stainless steel ball bearing but

previous experience with trying them on my traction engines had put me

off that idea. I had previously found that the Nitrile ball

could

become stuck in the seating hole which would prevent the injector from

operating, and Nitrile rubber's maximum operating temperature of 120

degrees Centigrade is less than the Stafford's boiler water temperature

of 172 degrees

Centigrade at 120 psi. Small Viton O Rings are quite easily

available and can operate at temperatures up to 200 degrees

Centigrade so they became my preferred option.The photo shows a completed O Ring clack valve with an original Stafford ball bearing clack valve inset for size comparison. The component parts of the O Ring clack valve are also shown in the photo with a "shuttle" shown in its "as machined" state and after fitting with its O Ring. O Ring clack valves require the O Rings shuttle to be guided as it moves up and down (open / closed) so that the O Ring will seat around the hole in the inlet, unlike a ball bearing valve where the ball simply drops into the hole. This can be accomplished by having a fluted stem on the shuttle which slides up and down in the inlet port bore but that requires the inlet bore to be increased beyond the feed pipe bore so that the area available for the water to flow is maintained. This will obviously increase the dimensions of the clack valve. To overcome this size increase I decided to put the shuttle stem on the top of the shuttle and guide it by using a tubular extension of the valves top cap. The length and tapered end of the shuttle stem were made so that the stem could be engaged in the caps guide hole before the cap is screwed down to ease maintenance of the valve, and obviously the guide hole in the cap has an opening into the valve chamber at its upper end to avoid any possibility of the shuttle stem becoming hydraulically locked as it moves up into the guide hole. Full details of the O Ring clack valve can be obtained by downloading a JPEG copy of the CAD drawings by clicking here (use a "right click" and "save as" to download the image to your computer). Ideally the clack valves should be manufactured using gunmetal or phosphor bronze and stainless steel for the shuttle, but to initially test the valves I used the cheaper option of brass for the main components. So far the two valves have performed perfectly and have always completely closed no matter what has happened with the injectors. Why my original ball valves would not operate correctly is a mystery, but these valves have resolved my problem and have definitely become a permanent feature of my Stafford. |

||||||