|

|

|

Adding Injector Overflow Pipes

| Personally I think that this modification should be a standard factory fit on every Stafford because it makes the task of using the injectors so much easier for any novice driver. Throughout this websites pages on controls and driving, whenever the operation of the injectors was discussed the comment about "watching the injector overflow" keeps cropping up, but the injector is tucked away underneath the footplate and its short overflow cannot be seen by the driver. In the photos on this page the injector is the small black object to which most of the pipes converge. This modification simply extends the injector overflow to where it can be seen by the driver. | |

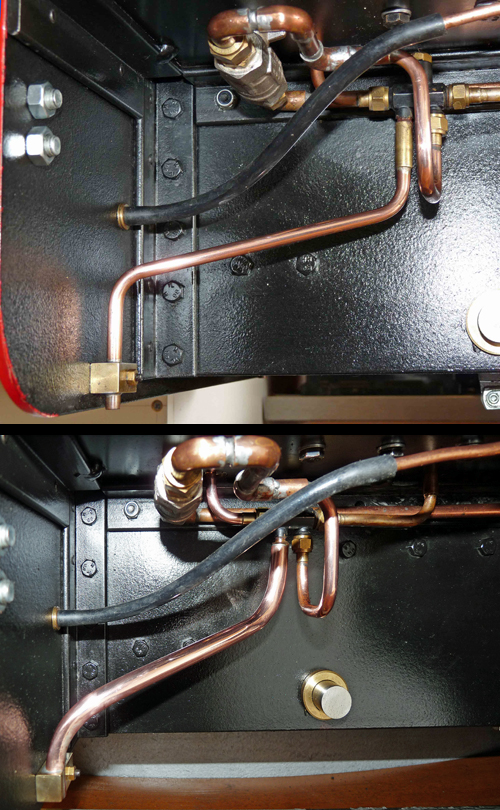

The composite photo on the left

show the injector overflow pipes fitted to Gentoo at different times

during 2011. The composite photo on the left

show the injector overflow pipes fitted to Gentoo at different times

during 2011.The upper half of the photo is of the original extensions, which were made using 1/4 inch OD by 22swg wall copper tube. At the injector end a short sleeve section was silver soldered to the copper tube so that it could be slid over the injector overflow pipe, and at the bottom the copper tube was soft soldered into a brass block that was bolted to the buffer beam. A smear of Copper Ease was applied to the injector overflow pipe before sliding on the copper extension to ensure that it could be removed again at a later date. Note that at the bottom the overflow extension ends just below the brass block to ensure that the flow from the pipe is "clean" and that the copper pipe ends just above the bottom of the buffer beam so that it is not crushed when the Stafford is clamped onto the travel blocks (see Storage and Transport page). The lower half of the photo shows the much larger overflow pipes, made from 10mm diameter "micro bore" central heating tubing that were fitted while trying to resolve the problem of the injector clack valves sticking open. These large pipes were tested to see if back pressure in the overflow was contributing to the clack problem. Using the larger size tubing made them much more difficult to make, and they had no affect what so ever on the injector clack valve problem. So if you decide to make a set of injector overflow pipes for your Stafford I would recommend using the 1/4" diameter pipe size. The benefit of both solutions is very easy to see when operating the Stafford as without them the driver cannot see what is happening with the injector unless steam is billowing out the side of the loco (showing that the injector isn't working properly). With the modification the driver only has to look down towards the bottom of the buffer beam to see if the overflow is passing water, steam, or hopefully nothing when the injector is operating properly. |

|