|

|

|

|

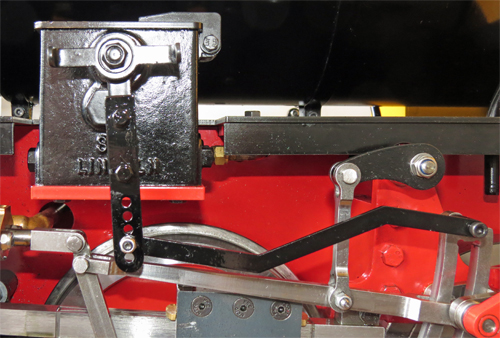

Stopping the lubricator over

oiling the cylinders

On

my

old Stafford (one of the first three built by Station Road Steam) the

lubricator had been driven from the cylinder slide

valve operating clevis, but on most other Staffords and all Feldbahns

the lubricator drive is taken from the top of the expansion link.

By watching video of my Stafford running (with the reversing

lever notched back) I found that the lubricator completed one rotation

for every twenty two turns of the driving wheels. On the

Feldbahn

the lubricator was rotating once for only fourteen turns of the driving

wheels because the top of the expansion link moves a lot further than

the notched back slide valve operating clevis. So the

solution to reducing the oil consumption was simply to

extend the arm of the lubricator as shown in the photo at the left by

bolting on an extension. I also inverted the link

between the expansion link and the lubricator arm because it looked

better "upside down" when connected to the longer lubricator arm. On

my

old Stafford (one of the first three built by Station Road Steam) the

lubricator had been driven from the cylinder slide

valve operating clevis, but on most other Staffords and all Feldbahns

the lubricator drive is taken from the top of the expansion link.

By watching video of my Stafford running (with the reversing

lever notched back) I found that the lubricator completed one rotation

for every twenty two turns of the driving wheels. On the

Feldbahn

the lubricator was rotating once for only fourteen turns of the driving

wheels because the top of the expansion link moves a lot further than

the notched back slide valve operating clevis. So the

solution to reducing the oil consumption was simply to

extend the arm of the lubricator as shown in the photo at the left by

bolting on an extension. I also inverted the link

between the expansion link and the lubricator arm because it looked

better "upside down" when connected to the longer lubricator arm.Tests on the Pinewood track quickly showed that this extended lubricator arm was providing the same amount of cylinder lubrication as had been present on my Stafford so it seems as if the modification is satisfactory. If you want to try it on your engine the extension is simply cut from 2mm thick mild steel sheet, 12mm wide by 76mm long. The holes attaching it to the original arm are drilled 4mm diameter on 24mm centres, starting 10mm from one end, to take a pair of M4 bolts with Nyloc nuts. From the lower attachment bolt there is a 12mm gap before the series of five 4mm diameter holes on 6mm centres starts. The original "Z" shaped operating arm is simply removed and inverted to align it as shown. Note that to remove the fixings at the expansion link end you need to remove the nut on the chassis side of the expansion link and then unscrew the socket cap head screw through both the expansion link and the spacer bush, both of which are threaded. When refitting the "Z" shaped link ensure that you leave enough slack in the two fixings so that the link can move freely. Note: The position of the link shown in this photo perfectly suited the Feldbahn when running "light engine" or pulling passenger trains around Pinewood. However when the engine was being pushed to its absolute limit at another railway (for 6 hours the Feldbahn was run in full forward gear and with an almost fully open regulator for virtually the whole of every lap of the track) more oil was required to compensate for the much larger volume of steam being used for the same track speed. This was simply achieved by moving the "Z" shaped link back up the lubricator operating arm. Please take care to match the oil flow to your operating conditions. My aim is simply to stop the Feldbahn from covering itself with steam oil without reducing the amount supplied to the cylinders too far. |