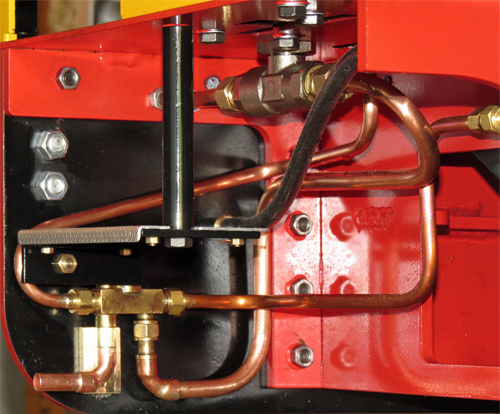

Injector System Modifications

Because

I had modified the Feldbahn to take the water for both injectors from

the driving truck (and disconnected both onboard water tanks) I had to

modify the injector plumbing. Also my experience of operating

a

Stafford locomotive had shown that the single biggest improvement in

injector reliability had come from relocating the injectors away from

the chassis frames adjacent to the firebox to a cooler location.

So even though different injectors are fitted to the Feldbahn

than those on my very early specification Stafford I decided that while

modifying the injector water feed pipes I may as well relocate both

injectors to a cooler location at the same time. The photo on

the

left shows where they ended up. Because

I had modified the Feldbahn to take the water for both injectors from

the driving truck (and disconnected both onboard water tanks) I had to

modify the injector plumbing. Also my experience of operating

a

Stafford locomotive had shown that the single biggest improvement in

injector reliability had come from relocating the injectors away from

the chassis frames adjacent to the firebox to a cooler location.

So even though different injectors are fitted to the Feldbahn

than those on my very early specification Stafford I decided that while

modifying the injector water feed pipes I may as well relocate both

injectors to a cooler location at the same time. The photo on

the

left shows where they ended up.

The injector was originally

connected to the pipe union that can be seen at the extreme right of

the photo. If I had left the injector there I would have

fitted

an extension to the injector overflow pipe that went to the same

position as the pipe at the bottom left of the photo. This

makes

the injector overflow very visible to the driver so that he can see

exactly what the injector is doing, a very useful feature if you have

problems operating injectors.

The new overflow outlet

assembly is silver soldered together and the bright (over exposed in

the photo)

brass mounting plate is bolted through the rear buffer beam of the

Feldbahn. The injector overflow pipe is a simple loose slide

fit

in the top of this overflow assembly. The water for the

injector

now comes from the front of the water valve via 8mm copper tubing to

allow as little resistance to the flow as possible and only contracts

to the 1/4" tubing required by the injector as it reaches the injector

gland nut.

The first test run of the Feldbahn showed that

everything worked satisfactorily, but I'll never know if the injectors

really needed relocating as I never did any trials with them in the "as

supplied" position. However to me that doesn't matter

and I'm happy with the revised installation.

|

|

|