Cylinder Drain Cock Outlets

As

soon as I started to drive my new Feldbahn from the steaming bay I

spotted a problem. The very first Stafford locomotives like

my

old 'Gentoo' had cylinder drain cocks that squirted vertically down, so

although they ended up splattering the underside of the loco with

trackside rubbish they didn't spray my friends in the steaming bays (or

worse members of the public in the station) with that nasty oily

emulsion that always appears when the loco has been standing.

The

photo on the left clearly shows the jet of liquid ready to soak anyone,

or any other loco, unlucky enough to be in its path. Not

wanting

to be considered antisocial by my fellow club members (or worse

upsetting a paying passenger by

scalding their feet or ankles) I decided that something had to be done

and set

about designing a solution. As

soon as I started to drive my new Feldbahn from the steaming bay I

spotted a problem. The very first Stafford locomotives like

my

old 'Gentoo' had cylinder drain cocks that squirted vertically down, so

although they ended up splattering the underside of the loco with

trackside rubbish they didn't spray my friends in the steaming bays (or

worse members of the public in the station) with that nasty oily

emulsion that always appears when the loco has been standing.

The

photo on the left clearly shows the jet of liquid ready to soak anyone,

or any other loco, unlucky enough to be in its path. Not

wanting

to be considered antisocial by my fellow club members (or worse

upsetting a paying passenger by

scalding their feet or ankles) I decided that something had to be done

and set

about designing a solution.

The

main problem was that I

didn't want to replace the existing cylinder drain cocks, so whatever I

did had to modify and not replace them. A simple angled

shield attached

to the cylinder cladding was considered but rejected because it would

have looked unsightly and probably have splashed the emulsion all over

the underside of the cylinders and

chassis. Measurements showed that there was insufficient

material

on the drain cock body to screw in pipe unions for outlet pipes, and if

pipes had simply been soldered on it would have been impossible to

screw the drain cock bodies back into the cylinder casting.

The answer

seemed to be an outlet pipe held to the drain cock body by some sort of

clamp, but the more I measured the more awkward this solution looked

because of the position of the cylinder cladding. Eventually

I

devised a solution, and although I could have directed the outlet pipes

straight down I pointed them forwards (as often seen on full size

locomotives) because generally speaking the track in front of a moving

engine is clear of people.

|

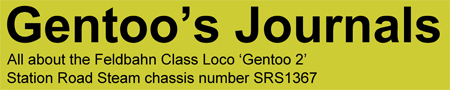

The

photo on the right shows the pair of outlet pipes ready for fitting to

the right hand cylinder of the Feldbahn. The clamp sections

were

machined on my lathe from 3/4" hexagonal section bar and bored to be a

good sliding fit onto the drain cock bodies. On my Feldbahn

this

was exactly 12mm diameter, although I did have to use

fine "wet

& dry" paper to remove the machining burrs from the drain cock

bodies

before the clamps would slide into place. My intention was to

have the clamps as good a fit as possible around the drain cock bodies

to avoid leaks. The 3/16" OD copper

pipes were bent on one of my home made pipe benders (see the bottom of

this page) and silver soldered into the clamps.

Likewise the

brass "figure of 8" section was silver soldered from brass tubing

before being soft soldered onto the outlet pipe of the forward

assembly. The clamps are locked in position on the drain cock

bodies by 4 BA socket grub screws. The

photo on the right shows the pair of outlet pipes ready for fitting to

the right hand cylinder of the Feldbahn. The clamp sections

were

machined on my lathe from 3/4" hexagonal section bar and bored to be a

good sliding fit onto the drain cock bodies. On my Feldbahn

this

was exactly 12mm diameter, although I did have to use

fine "wet

& dry" paper to remove the machining burrs from the drain cock

bodies

before the clamps would slide into place. My intention was to

have the clamps as good a fit as possible around the drain cock bodies

to avoid leaks. The 3/16" OD copper

pipes were bent on one of my home made pipe benders (see the bottom of

this page) and silver soldered into the clamps.

Likewise the

brass "figure of 8" section was silver soldered from brass tubing

before being soft soldered onto the outlet pipe of the forward

assembly. The clamps are locked in position on the drain cock

bodies by 4 BA socket grub screws.

A simple jig was used to

hold the parts together while soldering, and the clamp section was

drilled 3/16" diameter by 1mm deep to help locate the pipe.

The

pipe "hole" was drilled 4mm diameter right through the clamp, and as

the existing outlet hole in the drain cock body was only 2.6mm diameter

on my Feldbahn this allowed a degree of mispositioning to be tolerated

when attaching the clamps without blocking off the outlets.

The

photo on the left shows the outlets attached to the Feldbahn's cylinder

drain cocks. To fit them the M3 socket cap head screws in the

drain cock bodies and the operating bar had to be removed, which meant

that the short push rods inside the drain cock bodies fell out.

My tip for replacing them is to overlap half their length

onto a

short bit of masking tape which can then be used to get them back into

position while still allowing the M3 screws and operating bar to be

fitted. The masking tape can easily be pulled off before the

M3

screws are screwed into the second side of the drain cock bodies. The

photo on the left shows the outlets attached to the Feldbahn's cylinder

drain cocks. To fit them the M3 socket cap head screws in the

drain cock bodies and the operating bar had to be removed, which meant

that the short push rods inside the drain cock bodies fell out.

My tip for replacing them is to overlap half their length

onto a

short bit of masking tape which can then be used to get them back into

position while still allowing the M3 screws and operating bar to be

fitted. The masking tape can easily be pulled off before the

M3

screws are screwed into the second side of the drain cock bodies.

|

Finally,

here is a photo of the redirected drain cocks in action, and as you can

see they do what I wanted by getting rid of the sideways spray. Finally,

here is a photo of the redirected drain cocks in action, and as you can

see they do what I wanted by getting rid of the sideways spray. |

|

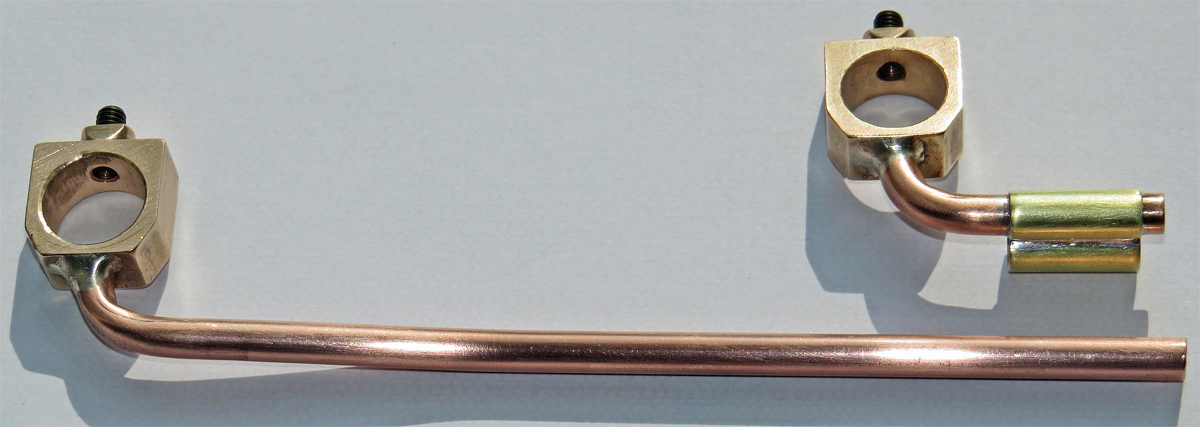

Miniature

Pipe Benders

The

outlet pipes needed to have a very tight bend radius which none of my

commercial pipe benders could produce so I had to build yet another

pipe bender (this is my third). All of my benders follow the

same

basic design as this one (shown in the photo on the left) although

those for larger diameter pipes (5/16" and above) incorporate another

bar across the top to "stiffen" the bender. The

outlet pipes needed to have a very tight bend radius which none of my

commercial pipe benders could produce so I had to build yet another

pipe bender (this is my third). All of my benders follow the

same

basic design as this one (shown in the photo on the left) although

those for larger diameter pipes (5/16" and above) incorporate another

bar across the top to "stiffen" the bender.

The main handle

is cut from steel angle, so that the upright section locates the pipe

while being bent. The other handle has a brass die block

bolted

to it which has a half round hole on the "bending" face the same

diameter as the pipe to be bent. The slowest job in building

these

benders (at least for me) is accurately grinding the form tool to be

used on the lathe when turning the mandrel around which the pipe

is bent. The quality of the finished pipe depends on getting

a

precise half round groove turned into the brass mandrel.

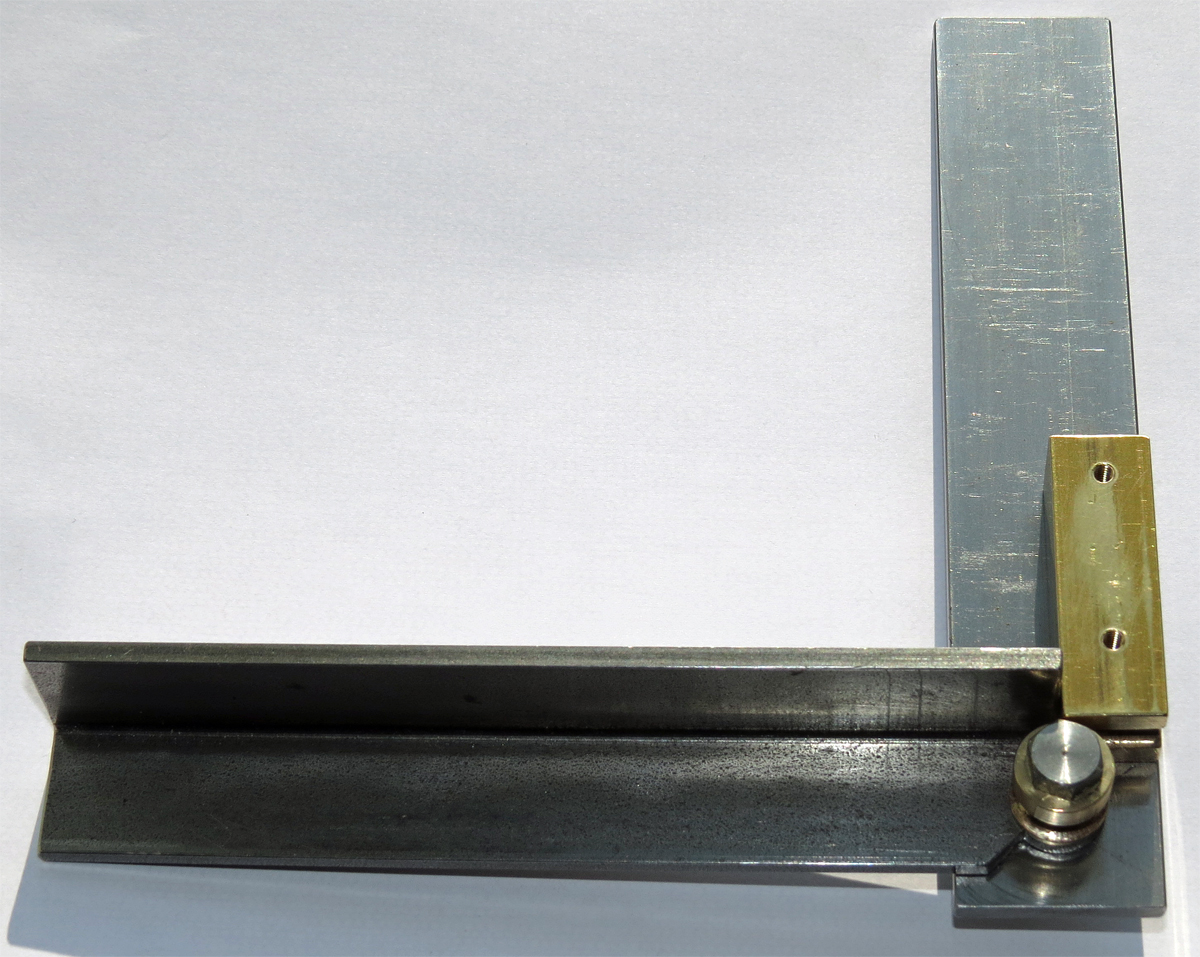

The

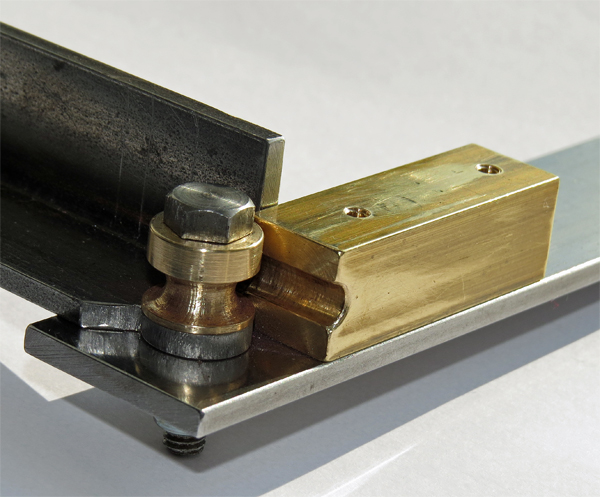

other photo shows a close up of the working parts of the bender.

By carefully positioning the pivot pin the mandrel and die

block

end up completely surrounding the pipe, and the upright angle section

will be supporting the outside of the pipes diameter. If the

supported length of pipe is short (and straight) it often helps to

insert a close fitting drill shank into the pipe end to stop the pipe

distorting as its forced against the upright angle, but don't let the

drill get too close to the start position of the bend or the pipe will

develop a bump (or even crack open) rather than forming a neat bend. The

other photo shows a close up of the working parts of the bender.

By carefully positioning the pivot pin the mandrel and die

block

end up completely surrounding the pipe, and the upright angle section

will be supporting the outside of the pipes diameter. If the

supported length of pipe is short (and straight) it often helps to

insert a close fitting drill shank into the pipe end to stop the pipe

distorting as its forced against the upright angle, but don't let the

drill get too close to the start position of the bend or the pipe will

develop a bump (or even crack open) rather than forming a neat bend.

With the

3/16" x 26 SWG

copper pipe correctly annealed this bender was able to produce bends

with an inside radius of only 4mm.

If

like me you have a "scrap" box full of odd lengths of material you will

probably have all you need to construct a pipe bender, and thus be able

to save money instead of purchasing a commercial item.

Another

benefit of this design is that the pivot bolt can easily be removed to

dismantle the bender and thus extract pipes with bends close together.

Both the commercial benders I own are riveted together with

the

result that it is often impossible to get bends close enough together. |

|