During

the first 2 1/2 years that I owned my Stafford I constantly had

problems with clack valves that would not reseat correctly and promptly

started emptying the boiler. This problem was not quite

unique to

my Stafford as I did witness it happen on another couple of Stafford's

on visiting engine days, but my Stafford seemed particularly prone to

clack failure. As a result I designed and built my own O Ring

clack valves, and from that day on I never had any further problems.

So as I was already modifying the injector system (see other

pages of this website) I decided to make a new pair of O Ring clacks

and fit them to the Feldbahn while the injector pipework was being

rebuilt. During

the first 2 1/2 years that I owned my Stafford I constantly had

problems with clack valves that would not reseat correctly and promptly

started emptying the boiler. This problem was not quite

unique to

my Stafford as I did witness it happen on another couple of Stafford's

on visiting engine days, but my Stafford seemed particularly prone to

clack failure. As a result I designed and built my own O Ring

clack valves, and from that day on I never had any further problems.

So as I was already modifying the injector system (see other

pages of this website) I decided to make a new pair of O Ring clacks

and fit them to the Feldbahn while the injector pipework was being

rebuilt.

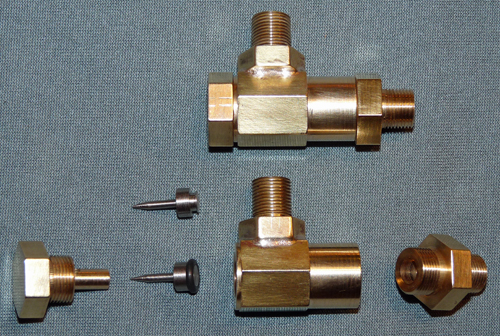

The photo on the left shows the parts of the O Ring

clack valve and shows the shuttle "as machined" and when fitted with

its O Ring. All the parts other than the shuttle, which is

Stainless Steel, are made from Phosphor Bronze and the O Ring is VITON

to withstand the temperature of the boiling water (172 degrees

Centigrade at 120 psi). Both the top

and bottom caps of the valve can easily be removed for cleaning, and as

the O Ring seat is on the face of the bottom cap there is no difficult

machining of blind holes / valve seats to do. It takes me

about 1

1/2 days in the workshop to make a pair of valves but their performance

is superb and having used them for 18 months on my Stafford I am

convinced of their superiority over normal ball valve clacks.

The

only downside is that the O Rings need to be replaced after about 50

hours use as they tend to flatten and leak when there is no

boiler pressure (e.g.

before steam is raised).

O

Ring clack valves require the shuttle that carries the O Ring to be

guided as it moves

up and down (open / closed) so that the O Ring will seat around the

hole in the inlet, unlike a ball bearing valve where the loose ball

simply

drops into the hole. This can be accomplished by having a

fluted

stem on the shuttle which slides up and down in the inlet port bore but

that requires the inlet bore to be increased beyond the feed pipe bore

so that the area available for the water to flow is maintained.

This will obviously increase the dimensions of the clack

valve.

To overcome this size increase I decided to put the shuttle

stem

on the top of the shuttle and guide it by using a tubular extension of

the valves top cap. The length and tapered end of the shuttle

stem were made so that the stem could be engaged in the caps guide hole

before the cap is screwed down to ease maintenance of the valve, and

obviously the guide hole in the cap has an opening into the valve

chamber at its upper end to avoid any possibility of the shuttle stem

becoming hydraulically locked as it moves up into the guide hole.

Full details of the O Ring

clack valve can be obtained by

downloading a JPEG copy of the CAD drawings from the Stafford section

of this website by clicking

here

(use a

"right click" and "save as" to download the image to your computer). |