When

I ordered my Stafford from Station Road Steam in 2009 they refused to

fit a whistle of any kind to the locomotive so I had to fit my own, and

as you will see if you read the Stafford pages of this website getting

it to sound cleanly without spluttering to life as it expelled

condensed steam took me some time. When I traded in the

Stafford

for the Feldbahn I had expected SRS to be offering a whistle that

worked nicely and so I was quite disappointed to find that the whistle

valve they fitted constantly leaked and water ran freely from the

whistle down the boiler cladding. This looked unsightly but

the

worst part of it was that every time you sounded the lovely chime

whistle it spluttered into life imitating a decrepit fountain. You can

see the water collecting around the base of the whistle in this photo. When

I ordered my Stafford from Station Road Steam in 2009 they refused to

fit a whistle of any kind to the locomotive so I had to fit my own, and

as you will see if you read the Stafford pages of this website getting

it to sound cleanly without spluttering to life as it expelled

condensed steam took me some time. When I traded in the

Stafford

for the Feldbahn I had expected SRS to be offering a whistle that

worked nicely and so I was quite disappointed to find that the whistle

valve they fitted constantly leaked and water ran freely from the

whistle down the boiler cladding. This looked unsightly but

the

worst part of it was that every time you sounded the lovely chime

whistle it spluttered into life imitating a decrepit fountain. You can

see the water collecting around the base of the whistle in this photo.

I

lived with this for over a year while other more important tasks were

tackled but finally the time arrived to solve the problem.

The

root cause of the problem was simply that the commercial whistle valve

fitted by SRS always leaked slightly, and resultant slow flow of steam

condensed in the pipe leading to the whistle where it then dribbled

out. I had learnt from the Stafford that metal on metal valve

seats rarely seal 100% against steam at boiler pressure so what was

really needed was a whistle valve with a PTFE valve seat (or something

similar). As I couldn't find such a device for sale it seemed

that I had two alternatives; either to fit one of the R A Barker PTFE

seat whistles on the front of the cab and somehow rig up an operating

cord / chain or to design and make my own whistle valve. I

chose to design my own whistle valve for the simple reason that R A

Barker do not currently sell their excellent whistle valves with a

chime whistle fitted.

This page explains the reasons behind my design and gives details of

the whistle valve I created for the Feldbahn chime whistle.

|

The

starting point was to adapt my O Ring clack valve design which has proven to be leak free

by adding an operating push rod to open the

valve (click

here

to see the relevant page on the Stafford section of this

website). Unfortunately although my new design worked perfectly using

compressed air the first time it was tested with steam the O Ring blew

off the shuttle and the whistle valve would no longer close. With

no other shut off valve available I had to endure the shriek of the

whistle for about 15 minutes while I dropped the fire and got rid of

the boiler pressure. After that I redesigned the valve to use a

PTFE valve without the O Ring and this seems to have solved all my

problems. Throughout the design of the new whistle valve

I had the following objectives in mind: The

starting point was to adapt my O Ring clack valve design which has proven to be leak free

by adding an operating push rod to open the

valve (click

here

to see the relevant page on the Stafford section of this

website). Unfortunately although my new design worked perfectly using

compressed air the first time it was tested with steam the O Ring blew

off the shuttle and the whistle valve would no longer close. With

no other shut off valve available I had to endure the shriek of the

whistle for about 15 minutes while I dropped the fire and got rid of

the boiler pressure. After that I redesigned the valve to use a

PTFE valve without the O Ring and this seems to have solved all my

problems. Throughout the design of the new whistle valve

I had the following objectives in mind:

1) There should be a minimum of high pressure joints or seals.

2) The valve seat should be easy to machine e.g. not

at the bottom of a deep hole.

3)

The cross sectional area of the steam passageways had to be

equal

to (or greater than) that in the original factory fitted steam valve.

4)

The valve should fit directly to the existing steam manifold

and

not obstruct the use of the new R A Barker steam valves.

5) The valve should be operated by a lever as opposed to any

form of chain.

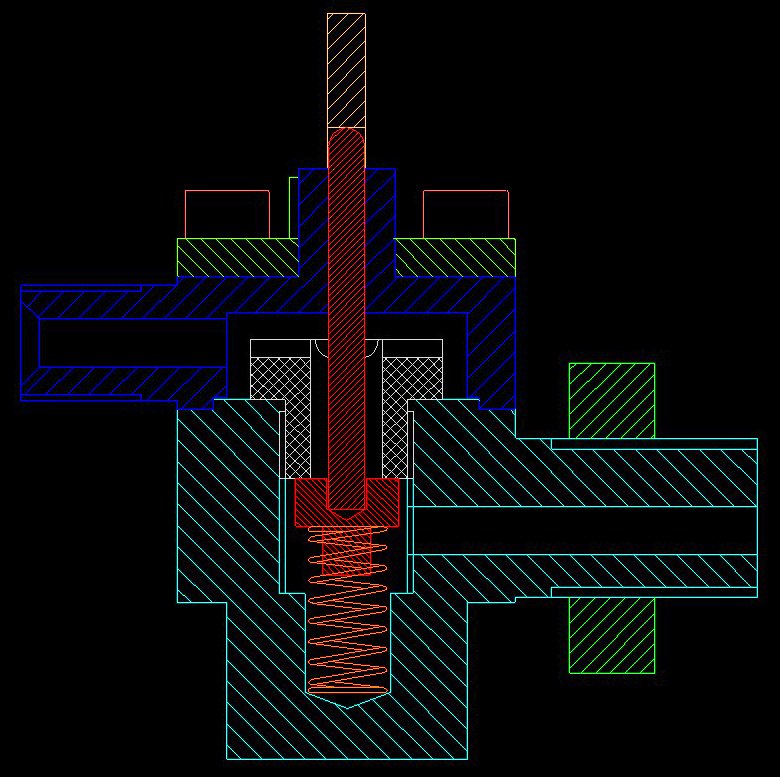

The

existing dimensions of the clack valve O Ring initially set the basic

dimensions of the new whistle valve and thus the valve spring, while

the original whistle valve gave a minimum cross sectional

area

for the steam passageways of 13 sq mm. A suitable stainless

steel

compression spring was easily sourced from ENTEX Springs but I then

spent hours using my CAD program sketching many potential valve designs

before I settled on the design shown here.

The drawing

reproduced from my CAD program shows the cross section through the

middle of the whistle valve. The main body of the whistle

valve

is shown in light blue and the spigot on the right screws straight into

the Feldbahn's steam manifold (1/4" BSP thread) and is locked in place

by the nut shown in green. Steam enters via the offset steam

passage to reach the valve chamber which contains the spring (light

brown) and the PTFE valve (red). The PTFE valve seats

against its valve face on the bottom

of the removable threaded bush (white). Experience of my O

Ring

clack valves had taught me that I could machine such a bush

and

main body face to be steam tight against the full boiler pressure.

The valve top cap (dark blue) is bolted onto the main valve

body

using M4 socket cap head screws, but being on the outlet side of the

valve this joint does not need to be so steam tight as the main valve

body components. Steam exits the valve top cap via the spigot on

the top left which is threaded 3/8"x32 to accept a normal 1/4" diameter

pipe nipple.

|

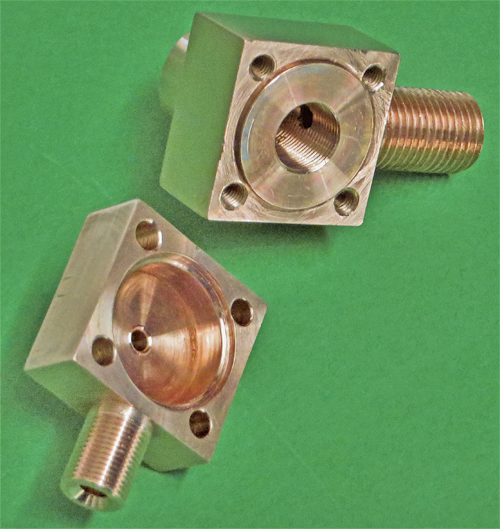

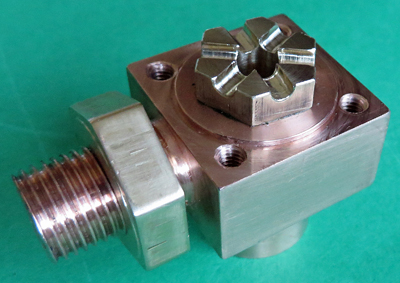

This

photo shows the whistle valve body (top) and valve cap (bottom)

machined from 1 1/4" square phosphor bronze bar. To save on metal they could

probably have been manufactured using several parts silver soldered

together but I had a suitable piece of bar so the parts were turned

using the four jaw chuck on my lathe. This

photo shows the whistle valve body (top) and valve cap (bottom)

machined from 1 1/4" square phosphor bronze bar. To save on metal they could

probably have been manufactured using several parts silver soldered

together but I had a suitable piece of bar so the parts were turned

using the four jaw chuck on my lathe.

Valve Body.

The

input spigot was the first part to be machined and then threaded 1/4"

BSP. Since the spigot is well offset from the centre of the bar

this operation has the most out of balance mass spinning on the lathe,

but by using a low spindle speed with shallow cuts at a low rate I

managed it without resorting to any counterbalance weights. The

part then needed to be offset again in the chuck to drill the inlet

steam port.

The face opposite the inlet spigot was then faced back to create the correct width of the valve body.

Turning

the part again in the chuck allowed the circular lower body (at the

back in the photo) of the valve to be turned before further

repositioning in the chuck allowed the remaining two sides to be faced

back. Obviously all of these operations had to end up with the

various faces correctly positioned with reference to the centre line of

the inlet spigot.

Finally the top face of the valve body was faced

off at +1mm from the designed body thickness, the various diameters

were drilled and tapped, and only then was the top face finally faced

to the correct thickness and the set back area turned to create the

raised boss that would locate the valve cap.

The four tapped holes that retain the cap to the body would be drilled later using the cap as a drilling guide.

Valve Cap.

This

was machined in a similar fashion to the valve body, spigot first with

its 3/8"x32 thread and outlet port and pipe nipple seat. Then the

sides were faced followed by the turning of the boss on the face

hidden from view in the photo. Finally the mating face of the

valve cap was faced and bored to create the main cavity. The

larger recessed diameter was machined to be a close fit over the raised

boss on the valve body, and the spindle hole was drilled through from

the cavity side to ensure concentricity. This hole needs to be a

close sliding fit for the valve operating rod so that the rod can slide

easily, but with the minimum of clearance to reduce the amount of steam

that can escape when the whistle valve is operated.

A simple jig was then

made that located over the boss on the top of the valve cap to allow

the four holes to be drilled through the cap at the tapping drill size

for the M4 bolts. The cap was then clamped to the valve body

(ensuring that it was correctly aligned) and the holes frilled down

into the valve body.

The body holes could then be tapped M4 while

the cap holes were opened out to clear the M4 stainless steel socket

cap screws that would hold the cap to the body.

Making these two parts took the best part of a day of lathe work.

|

The

1/4" BSP locknut was machined from a scrap piece of phosphor bronze

hexagon bar, remembering to relieve the hexagonal section on the mating

face so that the points of the hexagon would not scratch paint off the

steam manifold as the nut was tightened. You can just see the

relieved section in the photo. The

1/4" BSP locknut was machined from a scrap piece of phosphor bronze

hexagon bar, remembering to relieve the hexagonal section on the mating

face so that the points of the hexagon would not scratch paint off the

steam manifold as the nut was tightened. You can just see the

relieved section in the photo.

The removable threaded bush

that has the valve seat on its lower face was also machined from

phosphor bronze hexagon. This part looks easy to make but it

needs care to ensure that the valve face is really flat and without

burrs around the steam passage hole. Basically drill the steam

passage before facing the valve seat. The mating face between the

bush and valve body also needs to be really smooth with the thread

correctly relieved to ensure that the bush screws fully home into the

valve body where it will create a steam tight seal. Some Copper

Ease grease applied sparingly to the thread will help with the seal and

prevent the bush seizing into the body. You can just make out the

residue of the Copper Ease along the edges of the bush hexagons in this

photo.

The half diameter holes in the top face of the bush

are there to provide additional steam passage space between the bush

and the valve cap. These were drilled through the hexagon bar

before the face was turned to create the correct thickness.

|

This

photo shows the PTFE valve and the operating push rod. PTFE isn't

my favourite material to turn but the part didn't give me any real

problems. A 3mm diameter hole for the operating rod was drilled

3mm deep into the seating face before that face was finally faced off

by another millimetre. As before, making the part this way

results in less chance of burrs on the valve seating face than if the

hole was drilled after the face had been turned. The spigot on

the left of the photo was then formed using the parting tool. It

needs to be a slightly loose fit inside the coil spring. Finally

the valve was parted off and the finished valve face was inspected

using a magnifying glass. As I couldn't see any surface scratches

or imperfections I decided that it would probably be good enough to

provide a steam tight seal when the valve was closed. This

photo shows the PTFE valve and the operating push rod. PTFE isn't

my favourite material to turn but the part didn't give me any real

problems. A 3mm diameter hole for the operating rod was drilled

3mm deep into the seating face before that face was finally faced off

by another millimetre. As before, making the part this way

results in less chance of burrs on the valve seating face than if the

hole was drilled after the face had been turned. The spigot on

the left of the photo was then formed using the parting tool. It

needs to be a slightly loose fit inside the coil spring. Finally

the valve was parted off and the finished valve face was inspected

using a magnifying glass. As I couldn't see any surface scratches

or imperfections I decided that it would probably be good enough to

provide a steam tight seal when the valve was closed.

The

operating rod was simply a length of 3mm diameter stainless steel with

its ends faced off. As it needs to fit between the closed PTFE

valve and the valve lever with only a small amount of clearance I found

it easier to make this part after everything else had been completed.

|

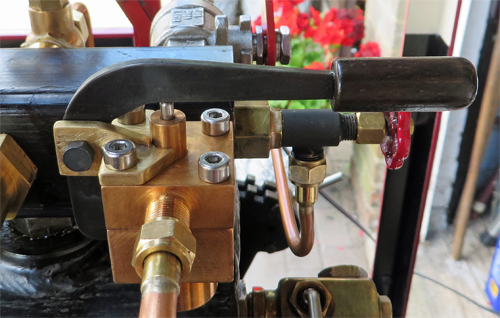

Here

is the finished whistle valve fitted to my Feldbahn. The

operating lever was cut from 3mm thick mild steel and has a varnished

wooden knob on the end. Note how the lever extends down below the

pivot on the left to act as a stop to prevent the lever from lifting up

further than necessary. The valve operating rod described in the

section above ends up with about 0.5mm of clearance between it and

the operating lever when the lever is fully "up". Here

is the finished whistle valve fitted to my Feldbahn. The

operating lever was cut from 3mm thick mild steel and has a varnished

wooden knob on the end. Note how the lever extends down below the

pivot on the left to act as a stop to prevent the lever from lifting up

further than necessary. The valve operating rod described in the

section above ends up with about 0.5mm of clearance between it and

the operating lever when the lever is fully "up".

The lever

pivot bracket was silver soldered from 3mm thick brass and the 4ba

pivot bolt is threaded into the pivot bracket. On the hidden

side, a 4ba Nyloc nut secures the lever and with careful adjustment

stops the lever from flopping about sideways to keep it centred over

the operating rod.

So

far the whistle valve has been working

well and no water has been seen weeping out of the whistle so I hope

that the leaky whistle valve problem has been solved. I have

deliberately avoided putting the CAD drawings on the website because so

far the valve is an experimental part, but if you would like a copy of

the CAD drawings then please contact me via the link at the top of the

page. |