Essential modifications to the

Vacuum Braking System

This

Feldbahn was ordered with a vacuum braking system, including the vacuum

limiting valve, as part of the factory build so I expected it to work

equally as well as the system that had been installed on the Stafford

which I owned

previously. Although the vacuum brakes were being used on the

Feldbahn's first run the ejector was somewhat ignored as all the

drivers who had a go were preoccupied with trying to

maintain enough steam pressure to keep the Feldbahn moving.

No matter what we

did, or how much steam blower we used, it was impossible to get the

boiler pressure about 85 psi. Having owned the

Stafford for

four years and having driven it almost 700 miles the Feldbahn's

performance was a real disappointment and so much steam blower was

being

used to maintain the 85 psi that the consumption of coal and water was

almost double that of the Stafford. The second run started

out in

the same fashion until I tried running without the vacuum brake system

operating. Instantly the Feldbahn came alive and the boiler

pressure easily stabilised at almost 120 psi, in fact once on the move

no steam blower was required and the firebox door had to be kept

slightly open to stop the safety valve constantly blowing off.

After trying it for themselves several different drivers all

came

to the same conclusion as I had; the vacuum braking system was

pressurising the smokebox and preventing the boiler from steaming

properly. I already knew that the ejector exhausted its steam

directly through a gland in the side of the smokebox which was

identical to the system that had worked so well on the Stafford, so why

was this engine performing so differently ? Obviously I was

going

to have to experiment to overcome the problem.

|

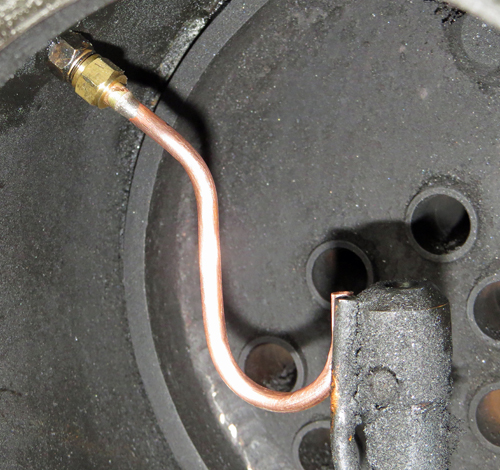

The

first experiment was to direct the ejector exhaust up the funnel.

In this photo you can see where the ejector exhaust entered

the

smokebox via the dirty gland nut at the top left corner of the photo.

As supplied there was nothing attached to this gland so the

exhaust steam just rushed into the smokebox (which was exactly the same

as it had been on the Stafford). I tried running the Feldbahn

with the ejector exhaust steam fed through the new pipe shown in the

photo,

but not surprisingly it operated exactly the same as the steam blower

did and the fire was now uncontrollable. After a couple of

laps

of the Pinewood track with the safety valve blowing constantly despite

the steam blower being turned off this experiment was deemed a failure. The

first experiment was to direct the ejector exhaust up the funnel.

In this photo you can see where the ejector exhaust entered

the

smokebox via the dirty gland nut at the top left corner of the photo.

As supplied there was nothing attached to this gland so the

exhaust steam just rushed into the smokebox (which was exactly the same

as it had been on the Stafford). I tried running the Feldbahn

with the ejector exhaust steam fed through the new pipe shown in the

photo,

but not surprisingly it operated exactly the same as the steam blower

did and the fire was now uncontrollable. After a couple of

laps

of the Pinewood track with the safety valve blowing constantly despite

the steam blower being turned off this experiment was deemed a failure.

|

The

next experiment was to simply dump the ejector exhaust steam directly

into the open air, so for this the pipe shown on the left was used to

take the exhaust underneath the footplate. The black painted

bar

at the bottom of the photo held the pipe firmly in place as it was

retained by one of the existing cab side bolts. This

configuration made a significant improvement as the Feldbahn now

steamed happily, and when compared to operating without the

vacuum

braking system in use only a small amount of additional steam blower

was required to maintain the boiler pressure at 120 psi when running

with the vacuum brakes operating. The possible downside to

this

configuration was that a constant plume of steam was being noisly

discharged

from under the footplate as shown in the photo. The

next experiment was to simply dump the ejector exhaust steam directly

into the open air, so for this the pipe shown on the left was used to

take the exhaust underneath the footplate. The black painted

bar

at the bottom of the photo held the pipe firmly in place as it was

retained by one of the existing cab side bolts. This

configuration made a significant improvement as the Feldbahn now

steamed happily, and when compared to operating without the

vacuum

braking system in use only a small amount of additional steam blower

was required to maintain the boiler pressure at 120 psi when running

with the vacuum brakes operating. The possible downside to

this

configuration was that a constant plume of steam was being noisly

discharged

from under the footplate as shown in the photo.

The

experiments had already shown that to maintain a vacuum of 15 in Hg the

ejector required quite a lot of steam with the standard control valve

having to be opened about 1/8 to 1/4 of a turn. In contrast

the

ejector fitted to the Stafford had required much less steam, and

because the steam valve had to be opened so little (it was almost

impossible to adjust it for the minimum amount of

steam required)

I had actually fitted a fine control needle valve to the Stafford.

So far as I could tell the ejector fitted to the Feldbahn was

using far more steam than that supplied with the Stafford, and

presumably that was why it pressurised the smokebox and so severely

limited the ability of the boiler to raise steam.

This was

as far as my experiments progressed in 2014. I knew what was

wrong with the vacuum braking system supplied by Station Road Steam but

despite talking with them neither of us knew why it was so different to

that which had operated faultlessly on the Stafford. |

|

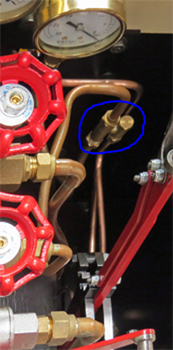

For

the 2015 running season something had to be done. So far as I

could tell the problem was being caused by the ejector apparently

requiring far more steam to operate than the ejector fitted to the

Stafford had required. PNP Railways manufacture an ejector

which

they claim has "a low steam consumption" and can operate at boiler

pressures up to 120 psi so I decided to purchase one and see how that

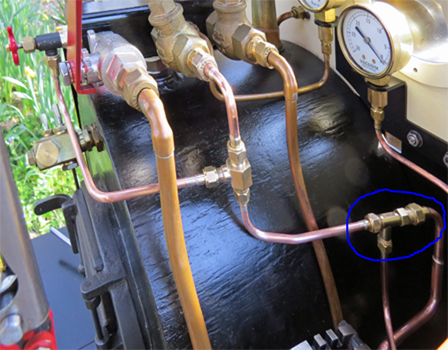

worked. The photo on the left shows the Feldbahn vacuum brake

ejector system as supplied by Station Road Steam. The ejector

(ringed in blue) is designed to work in the vertical plane so all the

pipes connecting to it run either straight up or down. The

problem with the PNP ejector was that it required the vacuum

pipe

section (containing the non return valve) to be vertical but the other

connections are then in the horizontal plane. You can see

this in

the photo on the right where the ejector is again ringed in blue. For

the 2015 running season something had to be done. So far as I

could tell the problem was being caused by the ejector apparently

requiring far more steam to operate than the ejector fitted to the

Stafford had required. PNP Railways manufacture an ejector

which

they claim has "a low steam consumption" and can operate at boiler

pressures up to 120 psi so I decided to purchase one and see how that

worked. The photo on the left shows the Feldbahn vacuum brake

ejector system as supplied by Station Road Steam. The ejector

(ringed in blue) is designed to work in the vertical plane so all the

pipes connecting to it run either straight up or down. The

problem with the PNP ejector was that it required the vacuum

pipe

section (containing the non return valve) to be vertical but the other

connections are then in the horizontal plane. You can see

this in

the photo on the right where the ejector is again ringed in blue.

The

installation of this ejector required a lot of new pipes to be made,

and as it was supposed to use less steam I decided to fit a small steam

valve to give finer control of the steam supply to the ejector in the

same way as I had on the Stafford. Thankfully the steam

manifold

already had a spare port in it's end above the firebox door so the

needle

valve was fitted there and plumbed into the ejector steam pipe using a

"T" piece connector.

On test this PNP ejector was found to

use less steam than the original Station Road Steam item, which wasn't

surprising as inspection had shown that the hole in its steam cone was

just under half the diameter of the original one. Currently

the

large (original) steam valve is only used to create the initial vacuum

in the train pipe and coaching stock. Once the required 15 in

Hg

is achieved the large steam valve is completely closed and the needle

valve is opened about 3/16 to 1/2 a turn depending on how much the

coaching stocks vacuum system leaks. This still gives quite a

cloud of steam under the footplate but at least the sound of escaping

steam is much less than it had been. The obvious question is,

could the ejector exhaust now be put back into the smokebox ?

Sadly at the moment I can't be bothered to find out as I'm

busy

with other projects but if I do ever get around to further experiments

then this page will relate what happens. |

|