Although my

Stafford and Feldbahn had both primarily been used for pulling

passenger trains I had always wanted to build and own some wagons of my

own, so when I joined a society that did not conduct public running

that

desire had to be turned into a reality. My original idea was

to

build some simple wagons that could carry all the tools, cameras, lunch

boxes, etc. that always accompany me when running the Feldbahn but when

I saw this narrow gauge guards van at the Hollycombe Steam Museum I

changed my plans. Although my

Stafford and Feldbahn had both primarily been used for pulling

passenger trains I had always wanted to build and own some wagons of my

own, so when I joined a society that did not conduct public running

that

desire had to be turned into a reality. My original idea was

to

build some simple wagons that could carry all the tools, cameras, lunch

boxes, etc. that always accompany me when running the Feldbahn but when

I saw this narrow gauge guards van at the Hollycombe Steam Museum I

changed my plans.

Due to the problems of fitting the

Feldbahn and its driving truck plus a wagon into my car I had already

decided that any wagon would have to have a lightweight chassis with

removable flat panels so that the parts could be fitted around the

engine and truck already in the car. I reckoned that a guards

van

would only have one more panel than a simple wagon and that although

they would be taller the panels would still fit into the car,

so

the guards van was sketched out using my CAD program. If you

have

looked at my webpage about the Hymek diesel you may have noticed that

I already owned a wagon that was used with it but I was

convinced that

a much lighter chassis was now required. That wagon used a

Ride

on Railways 7 1/4" gauge driving truck chassis but the chassis and

wheels alone were almost a two man lift.

|

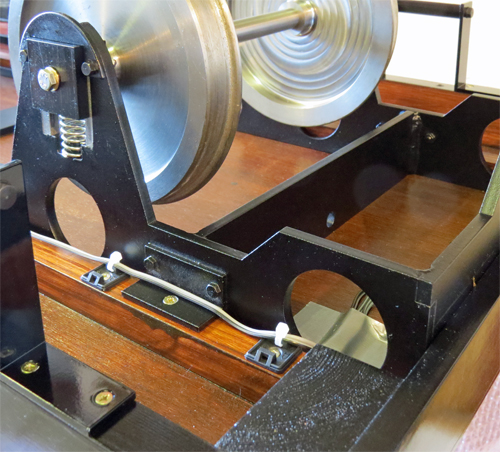

I

already owned a pair of lightweight chassis side rails and several sets

of suitable, but too heavy, wheels so I machined out the inner

faces of

four wheels to make them very much lighter. The wheel discs

ended

up just 3mm thick but that is more than enough for the weight of the

guards van and its intended load. The photo shows how the

chassis rails had been laser cut with lots of holes to save weight and

you can also see the wooden frame that forms the base of the guards van

which uses a sheet of 4mm thick Birch plywood for the main deck.

The entire chassis complete with the wooden deck and wheels

is an

easy lift for a single hand so my light weight target was certainly

achieved. I

already owned a pair of lightweight chassis side rails and several sets

of suitable, but too heavy, wheels so I machined out the inner

faces of

four wheels to make them very much lighter. The wheel discs

ended

up just 3mm thick but that is more than enough for the weight of the

guards van and its intended load. The photo shows how the

chassis rails had been laser cut with lots of holes to save weight and

you can also see the wooden frame that forms the base of the guards van

which uses a sheet of 4mm thick Birch plywood for the main deck.

The entire chassis complete with the wooden deck and wheels

is an

easy lift for a single hand so my light weight target was certainly

achieved.

I

also chose to use simple plain axle bearings because they would only be

lightly loaded, so the axle boxes were machined from scrap Delrin bar.

Being very easy to machine all four axle boxes were completed

in

a single morning. Another possibly unusual choice was my

decision

to make each axle in three parts. The centre main axle

section

has its ends turned down to fit into the wheels with the machined

sections not quite reaching all the way through the wheels.

Each

stub axle has a large diameter section that butts against the outer

wheel face to act as a spacer between the wheel and the axle box while

a short turned section locates the stub axle into the wheel.

An

M6 bolt goes through the stub axle and tightens into the end of the

main axle. The advantage of this arrangement is that the

shorter

lengths of the parts meant that they would fit my small lathe and that

the stub axles can easily be replaced if they do eventually wear.

Whilst the arrangement probably isn't suitable for high loads

it's more than adequate for the guards van.

With

the chassis almost complete the last parts to be specified were the

suspension springs. Ride comfort obviously wasn't a priority

but

keeping the guards van on the rails is critical so the springs have to

allow the wheels to follow any undulations in the track. With

soft springs on a lightweight wagon like this guards van it's very easy

to end up with something that rocks and rolls about, especially as a

high percentage of the weight is quite high up, and a wobbly wagon is

more likely to derail. The solution that I use on all my

rolling

stock (including my driving truck) is to select springs that are almost

fully compressed under the normal load. With little, if any,

more

compression available the wagon (or whatever) can't wobble about and

every wheel has the maximum possible pressure available from its spring

to force the wheel onto the track over any undulations.

Thankfully the spring suppliers that I use all have websites

with

programs on them that let you enter the spring details you know,

diameter, free length, load etc. to produce a list of suitable springs.

For the guards van and pipe wagon this let me purchase the

perfect spring without any need to experiment with different ones.

In the photo on the right you can see that the suspension

spring

is almost fully compressed under the normal weight of the guards van

and its load with 8mm of downwards wheel travel available.

|

To

keep the guards van light the body panels were all made from 4 mm Birch

plywood with 16 swg aluminium angle and strip for the frames and

detailing. All the panels were routed through their outer ply

layer to give the appearance of a planked construction and everything

was held together with "no slot" steel roundhead 5BA screws to give the

appearance of coach bolts. Additional aluminium angles were

used

on the inside faces of the side panels to create slots in which the

transverse body panels could slide. The photo on the right

shows

the front face of the van being slid into a side panel, and small

brackets were later added so that just four 2BA screws would

lock

the top aluminium angles together thus allowing for very easy assembly

and dismantling. To

keep the guards van light the body panels were all made from 4 mm Birch

plywood with 16 swg aluminium angle and strip for the frames and

detailing. All the panels were routed through their outer ply

layer to give the appearance of a planked construction and everything

was held together with "no slot" steel roundhead 5BA screws to give the

appearance of coach bolts. Additional aluminium angles were

used

on the inside faces of the side panels to create slots in which the

transverse body panels could slide. The photo on the right

shows

the front face of the van being slid into a side panel, and small

brackets were later added so that just four 2BA screws would

lock

the top aluminium angles together thus allowing for very easy assembly

and dismantling.

As this guards van was never intended to be

a scale model I took liberties in reducing the number of planks that

were routed, and hence the number of screws (coach bolts) needed to

assemble it. Even so there were over 250 sets of holes to be

drilled but that seemed better than the 600 plus if I had used narrow

"plank" widths.

|

The

removable roof used three 12mm Birch plywood cross braces cut with the

required top curve with five longitudinal beams made from triangular

section softwood mouldings. These beams were set into the

cross

braces so that the widest face aligned with the curve of the roof and

glued into place. Once the glue was set the top edges of the

assembled guards van body were then lined with aluminium cooking foil

to

stop any stray glue sticking the roof to the body panels and the 1/6"

thick Birch plywood roof panel was glued in place using slow drying

epoxy adhesive and a lot of luggage straps to hold the plywood sheet

against the roof sub structure. Whilst I normally use

waterproof

PVA adhesives for assembling wooden components the slow curing epoxy

adhesive was used here for two reasons. First it

allowed

sufficient time to apply the glue, but more importantly it is also

thick enough to fill any small gaps that may have existed between the

roof substructure and the roof sheet. The

removable roof used three 12mm Birch plywood cross braces cut with the

required top curve with five longitudinal beams made from triangular

section softwood mouldings. These beams were set into the

cross

braces so that the widest face aligned with the curve of the roof and

glued into place. Once the glue was set the top edges of the

assembled guards van body were then lined with aluminium cooking foil

to

stop any stray glue sticking the roof to the body panels and the 1/6"

thick Birch plywood roof panel was glued in place using slow drying

epoxy adhesive and a lot of luggage straps to hold the plywood sheet

against the roof sub structure. Whilst I normally use

waterproof

PVA adhesives for assembling wooden components the slow curing epoxy

adhesive was used here for two reasons. First it

allowed

sufficient time to apply the glue, but more importantly it is also

thick enough to fill any small gaps that may have existed between the

roof substructure and the roof sheet.

|

All

the finished external aluminium components were sprayed with etch

primer (ACID 8 is my preferred aerosol paint) and then finished with

gloss black using normal Halfords aerosol paint. The wooden

roof

assembly was given four coats of Ronseal Walnut (a suitable very dark

colour) quick drying varnish before the outside was sprayed using matt

black aerosol paint. The advantage of the Ronseal varnish is

that

with its one hour drying time you can easily apply and rub down four

coats in a single day to speed up the painting process. The

plywood panels were all painted using Johnstone's Universal Red Oxide

primer. It was the first time that I had used this paint and

I

was amazed by its quality. It brushed on easily and any brush

marks quickly disappeared, but best of all it created a nice smooth

thick layer of paint in only one coat. A quick rub down of

that

single coat was all that was required before the top coat of red oxide

could be applied. This was by far the best wood primer that I

have ever used. Once the top coat had dried the window and

door

frames were masked up and spray painted gloss white. All of

the

steel "coach bolts" were treated using Metal Blacking solution to avoid

the need for painting them. All

the finished external aluminium components were sprayed with etch

primer (ACID 8 is my preferred aerosol paint) and then finished with

gloss black using normal Halfords aerosol paint. The wooden

roof

assembly was given four coats of Ronseal Walnut (a suitable very dark

colour) quick drying varnish before the outside was sprayed using matt

black aerosol paint. The advantage of the Ronseal varnish is

that

with its one hour drying time you can easily apply and rub down four

coats in a single day to speed up the painting process. The

plywood panels were all painted using Johnstone's Universal Red Oxide

primer. It was the first time that I had used this paint and

I

was amazed by its quality. It brushed on easily and any brush

marks quickly disappeared, but best of all it created a nice smooth

thick layer of paint in only one coat. A quick rub down of

that

single coat was all that was required before the top coat of red oxide

could be applied. This was by far the best wood primer that I

have ever used. Once the top coat had dried the window and

door

frames were masked up and spray painted gloss white. All of

the

steel "coach bolts" were treated using Metal Blacking solution to avoid

the need for painting them.

The

windows were cut from mirrored finish acrylic sheet and are all held in

place by the internal aluminium framing with some silicone rubber

sealant applied to stop them rattling in their frames. I used

the

same technique as on my Hymek locomotive of lightly rubbing the

outer (non mirrored) surface of the acrylic with very fine wire wool to

remove the normal "vivid" reflections that mirrors provide. I

find

that this produces a dull mirror effect that looks far more like the

reflections you get from normal glass windows.

The photo

also shows the pipe wagon which was very quickly built onto

the

chassis of the Hymek's match wagon that was no longer required after

the Hymek had been sold. The chassis was originally from a

Ride

on Railways 7 1/4" gauge driving truck so all I needed to do was add

three pieces of 12mm Birch plywood and four sections of 19mm mild steel

angle to create a flat bed wagon. The pipe load is held down

by

19mm ratchet straps (which proved difficult to source) and can be

fitted with a saddle to allow a single passenger to ride along on the

train. Since the whole wagon was built from "stuff" I already

owned in under a day it proved to be a quick, cheap, and very useful

addition to my stock.

|

And

finally here's a photo showing how the guards van chassis travels in

the front passenger space of my car. Thankfully my ideas

proved

correct and all the guards van panels and roof fitted into the back of

the car around the Feldbahn and driving truck. Sadly there is

no

way to carry the pipe wagon at the same time but hopefully that will

eventually live at the Andover track. And

finally here's a photo showing how the guards van chassis travels in

the front passenger space of my car. Thankfully my ideas

proved

correct and all the guards van panels and roof fitted into the back of

the car around the Feldbahn and driving truck. Sadly there is

no

way to carry the pipe wagon at the same time but hopefully that will

eventually live at the Andover track.

You can see short video of the Feldbahn with these wagons by clicking

here.

|

| Postscript. |

| Since

writing this page my Feldbahn has been restyled to become a tender

locomotive (see the Cosmetic Modification pages) and that resulted in

me having another spare chassis. That has now been converted into

another wagon as explained below. |

The

driving truck from my Feldbahn already had vacuum brakes fitted so

because this wagon was intended to carry a heavy stone load I decided

to retain the braking system. A pair of new operating arms were

installed so that the vacuum servo mounted directly onto them between

the axles. The orange sphere in the top right of the wagon body

is a 6" (150mm) diameter plastic ball cock float that acts as a vacuum

reservoir. These are very much cheaper than the reservoirs sold

for vacuum braking systems but work just as well. All you need to

do is drill a small hole right through the brass rod bush and fit a

suitable pipe adaptor. The

driving truck from my Feldbahn already had vacuum brakes fitted so

because this wagon was intended to carry a heavy stone load I decided

to retain the braking system. A pair of new operating arms were

installed so that the vacuum servo mounted directly onto them between

the axles. The orange sphere in the top right of the wagon body

is a 6" (150mm) diameter plastic ball cock float that acts as a vacuum

reservoir. These are very much cheaper than the reservoirs sold

for vacuum braking systems but work just as well. All you need to

do is drill a small hole right through the brass rod bush and fit a

suitable pipe adaptor.

The vacuum piping and electric cables for

the train lighting system are all retained with cable clips and ties to

ensure that nothing can drop onto the moving parts or track.

|

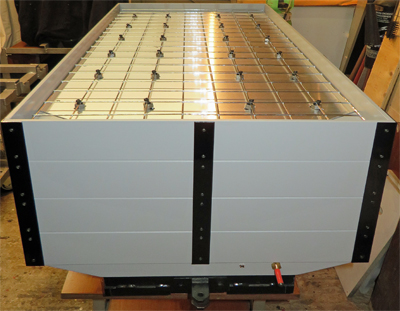

If

the wagon had simply been filled with stone chippings it would have

been very heavy (and a waste of chippings). But if only a thin

layer of chippings was used they could slide about on the false deck

and leave exposed areas of the deck in plain sight. My solution

was to fit a stiff wire grid cut from some fencing wire and spaced up

from the false deck using cable ties and M8 nuts. The stone

chippings were then held in place by the wire and the load appears to

be stable. If

the wagon had simply been filled with stone chippings it would have

been very heavy (and a waste of chippings). But if only a thin

layer of chippings was used they could slide about on the false deck

and leave exposed areas of the deck in plain sight. My solution

was to fit a stiff wire grid cut from some fencing wire and spaced up

from the false deck using cable ties and M8 nuts. The stone

chippings were then held in place by the wire and the load appears to

be stable. |

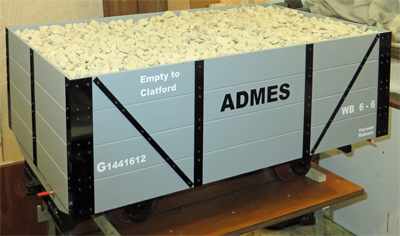

Here

is the finished wagon. The body was made from 6mm plywood, routed

to create the appearance of planks and the strakes are all aluminium

attached with black finish wood screws. With the addition of some

vinyl labels and the stone chipping load I think it makes a reasonable

narrow gauge wagon to go with my Feldbahn's other wagons. Here

is the finished wagon. The body was made from 6mm plywood, routed

to create the appearance of planks and the strakes are all aluminium

attached with black finish wood screws. With the addition of some

vinyl labels and the stone chipping load I think it makes a reasonable

narrow gauge wagon to go with my Feldbahn's other wagons. |