Of

all the modifications I have made to my Feldbahn, and the Stafford

before it, this is by far the most controversial. To some

having

a steam engine without injectors is almost sacrilegious while others

see it as a way of embracing modern technology, and surprisingly people

I have expected to take one stance have often taken the opposite.

My personal preference is to have injectors feeding the water

into the boiler simply because that's how it's done on a "real" steam

engine. So why have I made the change ?

After a couple

of years of tinkering I had the injectors on my Stafford working

perfectly and you can read all about those changes on the Stafford

pages of this website. All you had to do on the Stafford was

turn

on the water, turn on the steam, and water was fed into the boiler.

It was so reliable that you only needed to look down to see

when

the boiler had enough water in it. The Stafford had

eventually

covered over 500 miles and I hadn't even had to clean either injector.

So far as I was concerned the injector system was totally

reliable.

However

when I exchanged the Stafford for my Feldbahn, despite having modified

the injector system to incorporate all I had learnt from the Stafford,

I only did one lap of the Pinewood track before returning to the yard.

I simply could not operate the injectors while driving.

Eventually I learnt that the Feldbahn injectors needed

special

treatment. You had to turn on the water, turn on the steam,

then

throttle back the water until the injector picked up, then reopen the

water flow and set it "just so" depending on variables like boiler

pressure and temperature to keep the injector operating nicely.

This meant that the driver spent a lot of time looking down

at

the injector overflow and not where he was driving. Once I

had learnt the technique it wasn't really a problem on the

smooth

running

Pinewood track, but on rough tracks the injectors had a tendency to

stop on most of the track bumps. The driver thus had to go

through a full injector restart procedure, and just as you had got it

going you would hit the next bump and start all over again.

To

try to solve this annoyance I tried purchasing a couple of different

injectors but these either exhibited the same, or in one case, other

problems. I even resorted to asking Station Road Steam about

where they had purchased the Stafford's injectors but they were unable

to help.

Having left Pinewood driving

the Feldbahn just wasn't fun so I started investigating what could have

been wrong. Most of the basics for reliable injectors had

already

been covered. The output pipe to the clack was quite short,

the

bends were smooth with large radii, and the pipes were the same size as

on the Stafford with no obstructions in them. Assuming that

commercial injectors wouldn't be sold if they didn't work the obvious

thing to look at was the water feed to the injector. The

advice

here is generally that of making sure the injector can receive enough

water, so you don't want anything like tight bends or small pipes to

restrict the water flow. The head of water feeding the

injector

will also have an affect so the greater height of the Stafford's saddle

tank may help, but probably not by much. The

Stafford and

Feldbahn both use 8mm pipe to feed the injectors, and I had gone as far

as using 15mm pipe in the tender, dropping down to two 9mm pipes

linking the tender to my Feldbahn, and finally 8mm through the

footplate mounted valves. The injectors fitted to the

Stafford

and Feldbahn are rated at 2 2/3rd pints per minute, and with the

footplate valve output pipe removed measurements showed that much water

would flow out of the valve in 47 seconds. However if the

same

measurement was made at the end of the pipe normally connected to the

injector it took 135 seconds for the 2 2/3rd pints to flow.

This

is half the rate that the injector is supposed to move so the injector

actually has to suck the feed water from the tank. The reason

for

this restriction is the injector design. All the of the

injectors

we normally fit to the Stafford's or Feldbahn's use a 3/8"x32 union nut

and

nipple for 1/4" diameter pipe, and it's the restriction of that nipple

that drastically reduces the flow rate. The Stafford had the

same

restriction and worked satisfactorily, but I can't help wondering if

this design restriction is actually part of the problem.

Since I

don't have the capabilities of making my own injectors I will never

know.

Anyway, for several years I have been watching the

price of suitable electric pumps fall and while pondering what I was

going to do about the Feldbahn's injectors I spotted that I could now

buy two pumps and a battery to operate them all day for less than the

price of a single injector. Having purchased a pump I tested

it

while conducting a steam test on the Feldbahn and was very

impressed by its capabilities and quiet operation. On test

with

the boiler at 120 psi the pump happily fed 3 pints per minute into the

boiler, which is slightly more than the injector is supposed to do.

That basically settled any doubts in my mind; my Feldbahn was

going to have an electric pump fitted to improve the reliability of the

boiler water feed.

Having

decided that I was going to

fit an electric pump the problem was where to fit it. My new

tender

for the Feldbahn had not been designed to have space for the pump, and

wherever it ended up on the tender I was going to have to install a

high

pressure feed pipe between the tender and engine. It was all

looking a

bit difficult until I suddenly realised that the pump would fit very

nicely inside the original water tank space on the Feldbahn.

Putting

the pump there also meant that the high pressure piping was all on the

Feldbahn and the existing tender to engine plumbing that had been

feeding the injector could now feed the pump. From then on it

was no

longer a case of fitting one pump to back up the remaining injector.

My Feldbahn would now have two electric pumps and no

injectors !

|

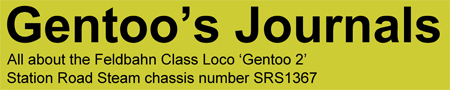

Electric

pumps of this type are sold with a variety of maximum pressure and

supply voltage ratings with the cheapest only costing about £12 (as of

August 2016) so you can select a pump to suit most model steam engines.

The pump I chose for use on the Feldbahn is generally

advertised

as being suitable for use in misting systems (air / moisture

conditioning) or for window cleaning (those long pole cleaners you see

being used to clean office block windows). The Pro Pump 160

operates from 12 Volt d.c. and is advertised as being capable of

providing 160 psi and of pumping 8 litres per minute. It's

rated

at 100 Watts (e.g. 8.3 Amps on 12V) and it also incorporates a limit

switch to stop the pump if the output pressure exceeds 160 psi. Electric

pumps of this type are sold with a variety of maximum pressure and

supply voltage ratings with the cheapest only costing about £12 (as of

August 2016) so you can select a pump to suit most model steam engines.

The pump I chose for use on the Feldbahn is generally

advertised

as being suitable for use in misting systems (air / moisture

conditioning) or for window cleaning (those long pole cleaners you see

being used to clean office block windows). The Pro Pump 160

operates from 12 Volt d.c. and is advertised as being capable of

providing 160 psi and of pumping 8 litres per minute. It's

rated

at 100 Watts (e.g. 8.3 Amps on 12V) and it also incorporates a limit

switch to stop the pump if the output pressure exceeds 160 psi.

In

practice the 8 Litres per minute only occurs when the pump is not

providing water against any pressure, and my measurements show that it

pumps 1.7 Litres per minute (3 Pints per minute) against the 120 psi

boiler pressure while drawing just over 5 Amps from the 12 Volt battery.

The

revised body style of my Feldbahn no longer has the two bolts that

previously retained the water tank, and without removing the cab I

could not drill any suitably inconspicuous holes to attach the pump

so I had to mount the pump using fixings that were

available. The large triangular plate to which the pump is

attached mounts at the top to one of the pressure / vacuum gauge

bracket bolts (depending on which side of my engine you are looking

at) and to the relevant spectacle plate bracing strut bolt.

At

the bottom are two rubber feet with the one fitted to the brass bush

being mounted on a length of studding. When the assembly has

been

positioned inside the water tank space and the top fixings are tight

the studding is adjusted to tightly brace the rubber feet across the

bottom of the water tank space.

The

flexible black tubing is sold for car fuel injection systems and rated

at 145 psi so it is adequate for the boiler pressure but I would be

relying on its designed factor of safety if a blockage caused the pump

pressure to rise to the 160 psi cut off. In order to not

exceed

the tubing's minimum recommended bend radius the pump's position within

the water tank space has been biased towards the front of the engine

which meant that copper pipe had to be used on one side of the pump to

create the tight bend radii. The copper pipe and threaded

output

connections at the bottom left all have lipped ends to help retain the

flexible tubing. The hose clips are standard automotive fuel

hose

clips.

|

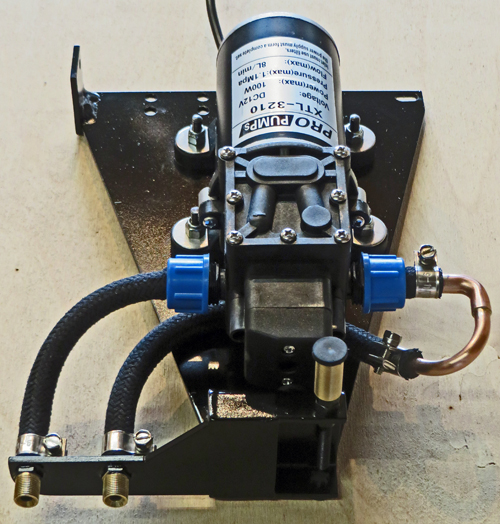

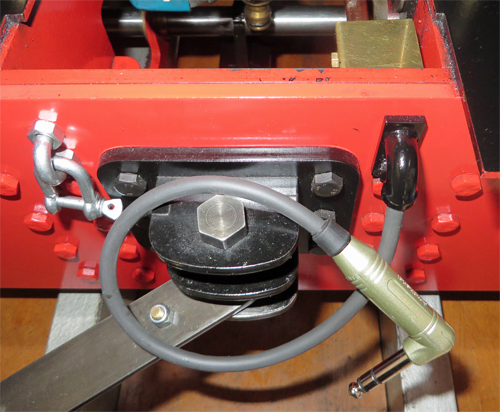

This

photo shows one of the pump assemblies installed inside the Feldbahn's

left hand water tank space. The yellow and black wires

supplying

the power for the pump are 18 AWG silicone wire rated at 16 Amps but

more importantly also rated for operation at 200 degrees Centigrade.

This is crucial as the wires have to run close to the firebox

where normal PVC wire insulation would melt. This

photo shows one of the pump assemblies installed inside the Feldbahn's

left hand water tank space. The yellow and black wires

supplying

the power for the pump are 18 AWG silicone wire rated at 16 Amps but

more importantly also rated for operation at 200 degrees Centigrade.

This is crucial as the wires have to run close to the firebox

where normal PVC wire insulation would melt.

The circular loop in

the wiring is a Service Loop which allows the wires to be longer than

needed so that spare wire is available in case the pumps have to be

removed

requiring the wires to be cut and then reconnected.

|

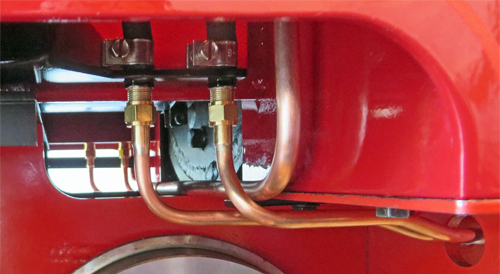

The

water connections to and from the pump use 1/4" diameter copper tube

with normal 3/8"x32 unions and pipe nipples. The pipes have

been

routed through the convenient hole in the footplate support.

The

larger 10mm diameter pipe in the photo provides a conduit for the pump

wiring and these L shaped pipes on each side of the engine are attached

to the footplate by means of silver soldered brackets and the

existing cab mounting bolts. Each wire conduit is a slide fit

into a copper tube T piece attached to the top of a conduit that runs

down and under the engine. Unfortunately that T piece is

impossible to photograph. The

water connections to and from the pump use 1/4" diameter copper tube

with normal 3/8"x32 unions and pipe nipples. The pipes have

been

routed through the convenient hole in the footplate support.

The

larger 10mm diameter pipe in the photo provides a conduit for the pump

wiring and these L shaped pipes on each side of the engine are attached

to the footplate by means of silver soldered brackets and the

existing cab mounting bolts. Each wire conduit is a slide fit

into a copper tube T piece attached to the top of a conduit that runs

down and under the engine. Unfortunately that T piece is

impossible to photograph.

|

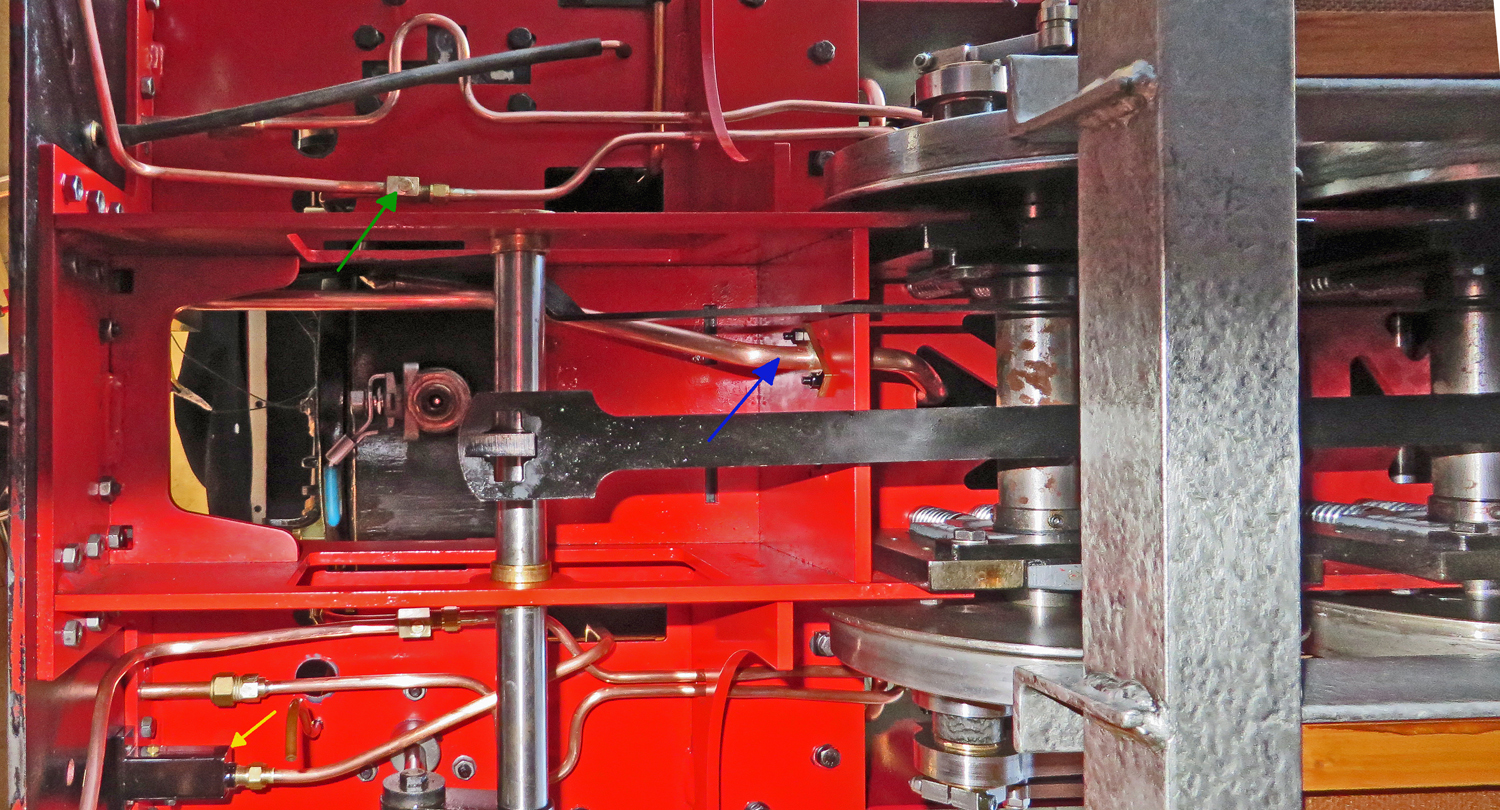

In

this unusual view from underneath my Feldbahn you can see how the pump

wiring conduit (blue arrow) has been routed through one of the holes in

the cross brace that appear to have been intended for an axle pump.

Nearer the rear axle the conduit runs vertically up to the T

piece mentioned above, and at the left of the photo the conduit ends at

the rear buffer bean underneath the removable section of the footplate.

The conduit thus protects the wires all the way from the

electrical junction box on the inside of the rear buffer beam to where

the wires enter the old water tank spaces. In

this unusual view from underneath my Feldbahn you can see how the pump

wiring conduit (blue arrow) has been routed through one of the holes in

the cross brace that appear to have been intended for an axle pump.

Nearer the rear axle the conduit runs vertically up to the T

piece mentioned above, and at the left of the photo the conduit ends at

the rear buffer bean underneath the removable section of the footplate.

The conduit thus protects the wires all the way from the

electrical junction box on the inside of the rear buffer beam to where

the wires enter the old water tank spaces.

The photo also

shows how the pipe between the pump and the boiler clack valve has a T

piece fitted (green arrow) with the teed section leading to a drain

cock on the inside of the rear buffer beam. This provides me

with

a simple way of draining the pipe when the Feldbahn is being stored.

The

pipe with the horseshoe shaped bend in it near the top left of the

photo is the pipe connecting the water inlet on the rear buffer beam to

the pump. Previously the buffer beam water inlets had been

connected to the footplate water valves but both of those valves had

now been removed and the holes in the footplate blanked off.

The

bend was created to allow some flexibility in the

pipes actual length because its shape has no natural way of allowing

for slight changes in its length due to it being a

dead straight "a to b" pipe. The pipe feeding the other pump

is

similarly bent although the bend is hidden behind the brake bar in the

photo.

Those of you familiar with Feldbahn's may be

wondering what the black box marked with the yellow arrow is.

That is the electrical junction box for the engines headlamp

wiring.

If you would like to see this photo as a larger image then please click

on it to open a larger version in a new window .

|

The

electrical connection between the Feldbahn and its tender uses a 3 core

silicone sleeved cable and a stereo jack plug. If you decide

to

use a similar method make sure that you purchase a jack plug that has a

suitable current rating. The ones I use were rated at 10 Amps. The

electrical connection between the Feldbahn and its tender uses a 3 core

silicone sleeved cable and a stereo jack plug. If you decide

to

use a similar method make sure that you purchase a jack plug that has a

suitable current rating. The ones I use were rated at 10 Amps.

Silicone

sheathed wire was again chosen for its ability to resist heat. If

you drop a hot ember from the fire on it you don't want the insulation

to instantly melt.

The

brass coloured square on the inside of the buffer beam is the

electrical junction box where the 3 core cable connects to the

individual wires leading to the two pumps. It also

has a

cable tie inside it acting as a retaining clamp to prevent the 3 core

cable from being pulled out of the buffer beam.

|

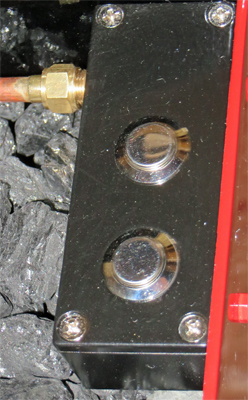

The

pumps are controlled by a pair of push button switches mounted in a

small die cast box located in the front left-hand corner of the tender

coal space. To prevent the switches getting jammed up by coal

dust etc. I used switches with an IP65 rating which means that they are

water and dirt proof. The

pumps are controlled by a pair of push button switches mounted in a

small die cast box located in the front left-hand corner of the tender

coal space. To prevent the switches getting jammed up by coal

dust etc. I used switches with an IP65 rating which means that they are

water and dirt proof.

Non latching push button switches were

chosen in place of latching switches (either push button or toggle

type) because they would ensure that the operator had to keep pushing

the button to pump water into the boiler. If a more

conventional

latching switch had been used the operator could leave the engine with

the pump running and thus overfill the boiler to the point where there

was no steam space left at all and water was blasting out of the safety

valve. That would potentially be a very nasty situation and

had

to be avoided.

|

This

photo shows the storage space inside my Feldbahn's tender where the 20

Ah battery for the electric water pumps is situated underneath the

wooden switch panel. There is still sufficient space for the

various oils and water treatment to be carried as well as some tools

and waterproof clothing. This

photo shows the storage space inside my Feldbahn's tender where the 20

Ah battery for the electric water pumps is situated underneath the

wooden switch panel. There is still sufficient space for the

various oils and water treatment to be carried as well as some tools

and waterproof clothing.

The wooden panel helps to hold the

battery in position and has the battery charging socket and power On /

Off switch mounted on it together with a 15 amp fuse in a holder on the left-hand side. The item with the green coloured

screen

on it is a power monitor for the pump's 12 Volt battery. If

you

have seen electric locomotives operating on a miniature railway you may

have noticed that they frequently incorporate coloured LED's to show

the drive batteries state of charge. For a 12 Volt battery

they

tend to have three LED's denoting full, OK or discharged. For

only a couple of pounds more you could have one of these power

monitors. The display shows not only the battery voltage but

also

the current being drawn from the battery; and on a cyclic section of

the display they show the total ampere hours drawn from switch on, peak

current drawn, and the elapsed running time. This is far more

useful than three LED's and as the unit can measure up to 180 Amps and

operate from a 24 Volt supply it can also be used to monitor the drive

batteries of most miniature railway locomotives.

|

Here

is a photo of the wattmeter's display when I was using it to monitor

the batteries of one of my electric locomotives. At the top

right

is the battery voltage (the locomotive used a pair of 12 Volt

batteries), with the current being drawn at the top left (the loco was

stationary when photographed and thus not drawing any significant

current. At the bottom left the cyclic display is showing the

total number of ampere hours drawn from the battery since switch on.

The bottom right shows the number of Watts supplied by the

battery. Here

is a photo of the wattmeter's display when I was using it to monitor

the batteries of one of my electric locomotives. At the top

right

is the battery voltage (the locomotive used a pair of 12 Volt

batteries), with the current being drawn at the top left (the loco was

stationary when photographed and thus not drawing any significant

current. At the bottom left the cyclic display is showing the

total number of ampere hours drawn from the battery since switch on.

The bottom right shows the number of Watts supplied by the

battery.

For little more than the LED monitor you get an

awful lot more information about the state of you battery and what has

been going on. By using this monitor I leant that the two

electric pumps on my Feldbahn used just over 2 ampere hours for a 5 1/2

hour steaming session covering 8.95 miles. The 20 Ah battery

I am

using thus has far more capacity than needed for a day at the track.

|

I

think that this page should provide all the information you need about

using electric pumps to replace the injectors on your model steam

engines. I am certainly extremely happy with their

performance

even though I would prefer to use injectors, but fitting the pumps has

made driving my Feldbahn enjoyable again as well as letting me

concentrate on where the engine is going rather than looking down at

the injector system.

Finally for those of you who would say

that an electric boiler feed pump has no place on a model locomotive I

would suggest that you consider the following fact. Full size

railway engines generally do not have axle pumps fitted, but how many of you are

happy to use them on your models ? |